Roof Coatings Special Section

More Roofing Contractors are Considering Coatings

Versatility, longevity and easier application methods offer efficiencies for roofing contractors.

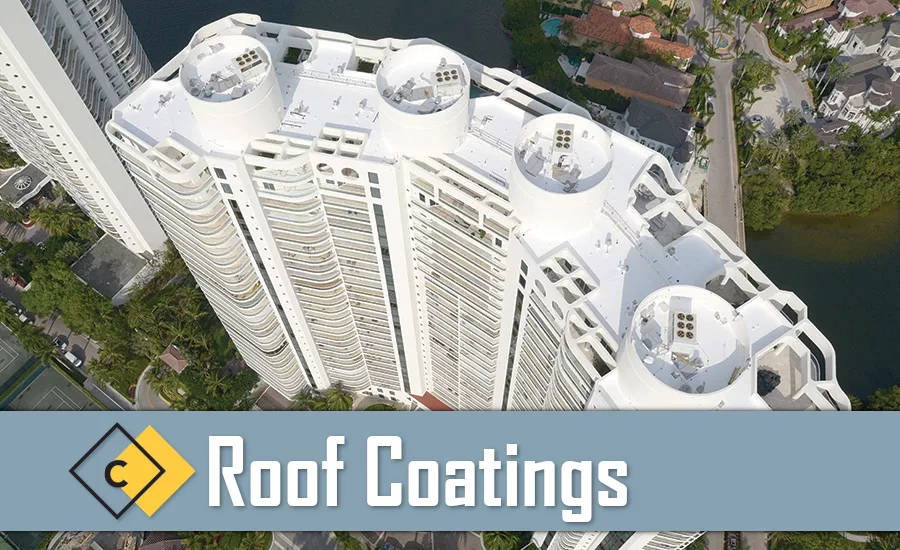

The condo association of this large residential complex in Hollywood, Fla., faced repeated repairs on aging flat roofs that were susceptible to water damage. The award-winning application of a silicone coating met both the client’s budgetary constraints and desire to extend the roof-life for years to come. Photos courtesy of Florida Quality Roofing.

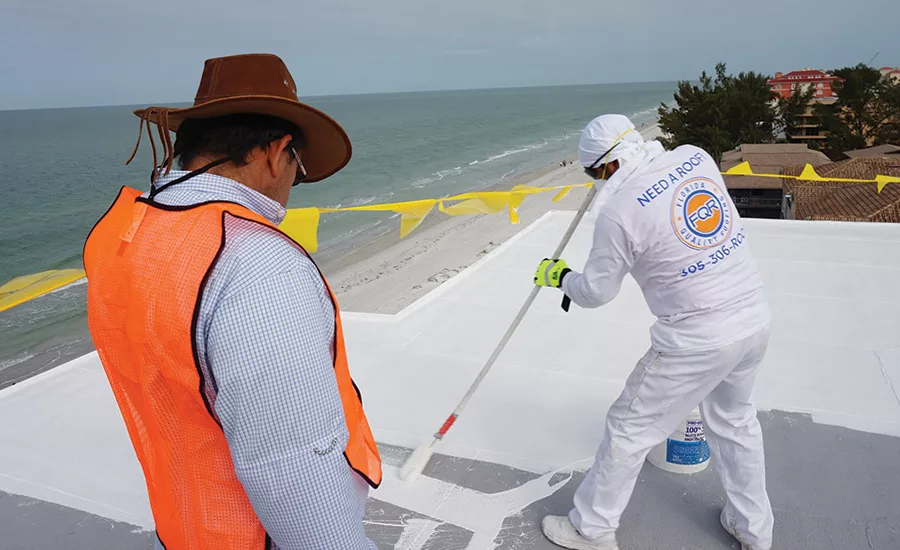

While the technology continues to improve, applying coatings by hand roller is still a widely-accepted, relatively safe and effective way for roofing contractors to help extend the life of an existing roof surface.

As a building ages, building owners will inevitably encounter a time when they need to address an aging roof. While a reroof is necessary in some situations, another solution is available: coatings.

Coatings — fully adhered membranes applied to existing roofs in a liquid form — are a highly effective solution that building owners can use to extend the life of a roof. They are also extremely versatile and can be used in most commercial, residential and industrial applications.

Current coating technologies have been effectively used in the market for more than 50 years, bringing time-tested durability to users. Today, they continue to evolve to provide efficient ways to maintain, waterproof and restore aging roofing systems. Certain coatings can even help substantially extend the life of a roof.

Benefits

Coatings can cover virtually any existing commercial roof type such as TPO, EPDM, PVC, metal, SBS, APP, and spray polyurethane foam (SPF). This versatility means building owners or contractors, regardless of building type, have many coating options to choose from, offering more flexibility when addressing an aging roof. While coatings should not be considered a “second roof,” they can be highly effective in preventing water, chemical or physical damage for extended periods of time.

Coatings also serve as an environmentally-friendly alternative to reroofing. They are renewable and can be reapplied as needed, and by restoring your existing roof, you are also reducing landfill waste. Many coatings are low or zero VOC and can qualify for LEED. Furthermore, coatings are an inexpensive way to convert the existing roof into a reflective roof, which reduces roof surface temperatures — ultimately reducing cooling costs — by reflecting visible light and ultraviolet (UV) and infrared radiation.

An additional significant saving for building owners is a coating’s ability to prolong the need to do a complete reroof, so long as the physical integrity of the roof is intact. Coatings also require lower material and labor costs. Finally, because many coatings contain low or no VOCs, businesses are able to continue operating with minimal interruptions while the roof is being repaired.

Coatings

Many coating technologies in the market today are primarily concentrated into three categories: acrylics, silicones and urethanes. Each coating type has unique characteristics.

• Acrylic Coatings

Acrylic coatings are water-based coatings widely used across the U.S. due to the reduced complexity of mixing components and cost-effectiveness. Acrylic coatings are easy to clean, offer UV stability and have low VOCs. They require multiple coats as they have lower water resistance. With this need in mind, it’s best to reapply acrylic coatings every three to five years.

• Silicone Coatings

Silicone coatings help restore existing roofs and create waterproof roofing systems. Silicones are typically solvent free, permanently-flexible liquids applied roofing (LAR) membranes. They provide resistance to ponding water and excellent UV stability. Additionally, silicone coatings can be applied to most substrates without the use of an additional primer. Silicones are available in a wide variety of colors for different applications. Additional benefits include long-term weathering and adhesion to various surfaces, such as single-ply membranes, metal, asphalt and SPF. Silicone coatings come with some of the longest warranties available, as they are unaffected by UV lighting.

• Urethane Coatings

Urethanes can be single or two-part coatings and offer varying degrees of UV stability. They are most commonly used on traffic decks, roof gardens, tanks, underground and for between-slab waterproofing. Key benefits of urethane coatings include abrasion and hail resistance, high tensile strength and excellent chemical resistance.

Selecting the right coating is contingent on multiple factors, including building type, climate, energy efficiency and the required longevity. For example, coatings that offer high reflectivity and emissivity are a priority for buildings in the South, while flexibility in low temperatures is important in the North. Manufacturers, roof consultants, industry experts and dealers can help you determine the best coating for your specific project.

When is a Coating Appropriate?

While coatings offer significant cost savings compared to a reroof, a coatings solution may not be feasible in all instances. Before moving forward with a coating, confirm if the roof substrate meets the following three criteria:

• Clean: The surface needs to be free of dust, dirt, organic growth and other contaminants, or delamination and/or blistering in the coating film may occur.

• Sound: Coating systems will not restore a roof covering that is deteriorated, rusted, or rotted to the point where it is no longer sound. Carefully evaluate the roof for any physical damage or vulnerabilities, such as tears or peeling, and repair these areas before applying a coating.

• Dry: Not only must the surface be dry to allow bonding of the coating, the entire roof system (insulation, roof deck) must also be dry. Entrapped moisture may cause failure in the coating system. Watch out for significant ponded water or a saturated substrate.

If the roof substrate does not meet all the above criteria, a coating may not be effective.

Coatings Installation

Airless spray machines and rollers are two common tools used for installation. Airless spray machines are one of the most economical and expedient ways to apply roof coatings, as they offer the flexibility to cover large roofs with minimal labor. Airless sprayers also pump the material directly onto the roof, which eliminates the need to haul material. These machines are best for large-scale coatings applications.

Roller application — applying the coating directly to the roof using hand rollers — can be an effective alternative for smaller roof jobs. Installers can use 3/8-inch to 1 ¼-inch nap natural rollers like those used when painting the interior of a house. For metal roofs, different roller sizes are available to match certain metal profiles for consistent coverage.

Regardless of installation type, always follow the manufacturer’s installation guidelines, even when recoating an existing roof coat.

The Takeaways

Coatings make it possible to restore a roof at a fraction of the cost of a conventional reroof, which leads to a long-term, viable system. Additionally, coatings offer ease of installation and convenience for building owners and are an environmentally-friendly alternative to reroofs. They’re also versatile and designed for countless applications.

Working closely with your product manufacturer will help ensure you select the best coating for your needs and that it is installed properly to achieve the desired performance.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!