Cool Roofing: It Takes More Than Reflectivity to be Cool

The main campus of Texas A&M University boasts more than 7 million square feet of spray-applied polyurethane foam (SPF) roofing, and almost no other system has been installed at the campus for more than 30 years. Why? Proven energy efficiency, waste reduction and environmental responsibility, as well as long-term performance.

It all started in 1974, when the Physical Plant Department at Texas A&M began exploring options for reproofing some of its aging buildings. The university selected SPF because it is seamless, monolithic and fully adhered. And because it is lightweight, a complete tear-off of the existing tar and gravel built-up roofing (BUR) systems could be avoided.

In 1985, Gerald Scott, P.E., then in charge of roofing and energy conservation within the Physical Plant Department, announced another benefit the university had been receiving from the SPF roofs: energy savings.

Scott monitored energy savings on 27 different buildings on the campus that had received an SPF roof from 1980 to 1984. The results showed the university was able to cover the complete cost of the roof application through energy savings in an average of 4.5 years.

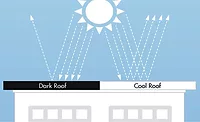

Surprised? You shouldn't be. All spray-applied polyurethane foam roofing systems require a coating to protect the foam from UV degradation and weathering. Many of the coatings used for this purpose are Energy Star rated to be reflective and utilize the albedo effect to reduce rooftop temperatures, just like white membranes or roll-on coatings.

But as the Texas A&M story shows, SPF brings more energy efficiency benefits to the table than simple reflectivity. For one thing, it offers an effective insulation R-value of 6 per inch (remember: the thicker the foam application, the higher the R-value). And because SPF is self-adhering and spray applied, it requires no fasteners and eliminates thermal bridging by providing a continuous layer of insulation over existing thermal bridges in the roof deck and assembly.

Waste Reduction and Environmental Responsibility

According to a 1999 survey conducted by the National Roofing Contractors Association (NRCA), more than 68.5 percent of the $11.3 billion low-slope roofing market includes tear-off and replacement of the existing roof. SPF is lightweight and can be applied to a variety of substrates including BUR, modified bitumen, concrete, wood, asphalt shingles, clay tile and metal as a recover system over existing roofs without tear-off in most retrofit cases. As noted by Cohen, that means significantly reducing the installation cost and diverting thousands of pounds of waste from the landfill on every reroofing project. It also means the building interior is never exposed to the elements.The Spray Polyurethane Foam Alliance (SPFA) reports that SPF's on-site manufacture and application generates very little debris and waste. A typical 10,000-square-foot roofing project produces less than a half cubic yard of scrap, tape and plastic, and from one pint to three gallons of waste solvent.

SPF is a two-component product that is manufactured on-site, but engineered on the molecular level to optimize performance for a specific application. Some SPF manufacturers are engineering those molecules to optimize life-cycle performance, maintenance cost and ecological footprint (which includes energy and raw material consumption, health effect potential, risk potential, emissions, and evaluation of land use and transportation fuel usage).1 A commitment to R&D for environmental stewardship has resulted in superior formulations. For example, BASF Polyurethane Foam Enterprises LLC has developed zero-ozone-depleting, VOC-free foams incorporating ZONE3® technology.

Long-Term Performance

Some of the oldest over-BUR SPF roofs on the Texas A&M campus are more than 30 years old. According to Cohen, they have received little to no maintenance due to manpower restraints, yet remain leak-free and retain their energy efficiency performance. On newer roofs, SPF was applied directly to the metal deck. Most of these roofs are now 10 to15 years old and Cohen reports that they perform as well as they did the day they were installed.The National Roofing Foundation commissioned Structural Research Inc. of Middleton, Wis., to perform independent field and laboratory assessments of SPF roof systems to establish and verify existing performance attributes. The published reports of the findings show that the physical properties of the 140 evaluated roofs (ranging in age from six months to 27 years, in four climatic zones) were positive regardless of the age of the installation and that these properties point to the durability of SPF.2

SPF offers a life span of 20 to 30 years with minimal maintenance. SPF roofing systems have received a variety of fire, wind uplift and hail resistance approvals. For example, the ELASTOSPRAY® SPF systems from BASF Polyurethane Foam Enterprises are UL classified Class A (over noncombustible decks, up to unlimited slope) and Class B over combustible decks. These systems are also FM Global FM 4470/4880 Class I approved, including wind uplift ratings of 1-90 over metal and up to 1-180 over asphaltic BUR wind uplift ratings, with severe and moderate hail resistance test approvals.

A primary cause of roof failure during severe weather is flying debris or hail actually puncturing the roof. Documentation on SPF systems gathered by Thomas L. Smith of TLSmith Consulting after Hurricane Andrew decimated Dade County, Fla., shows that even if debris punctures the foam straight down to the metal deck, the roof will not leak, and can remain unrepaired indefinitely without developing leak problems. Independent studies from the Performance Based Research Group (www.pbsrg.com) at Arizona State University show SPF systems also perform well in severe hail zones.

Spray-applied polyurethane foam roofing systems offer proven, long-term energy efficiency and durability performance benefits. Chemical cleverness and an industry-wide commitment to research and development have resulted in environmentally responsible formulations that can withstand severe weather while diverting waste from landfill and lowering life-cycle costs. And that's more than cool roofing - it's just plain cool.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!