DuPont Celebrates 60th Anniversary of DuPont Tedlar

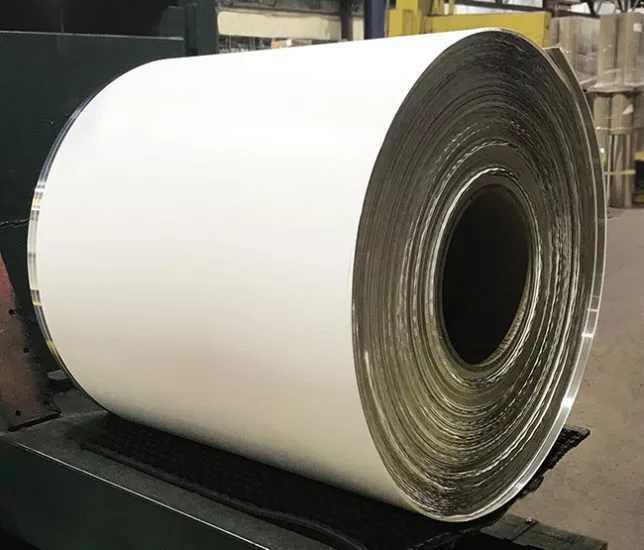

Roll of Splendid White Tedlar®-laminated aluminum produced by Metal Alliance. Photo by DuPont.

WILMINGTON, Del. — DuPont announced the 60th anniversary of DuPont™ Tedlar®, a unique brand of polyvinyl fluoride (PVF) film that has become a golden standard, synonymous with superior protection, durability and reliability in a wide variety of industries and applications, from photovoltaics and aerospace to transportation, building and construction, and wallcoverings.

“We are proud of the role Tedlar has played during the past 60 years in protecting assets for the long-term,” said Eric Wang, global business director for DuPont Tedlar. “From providing electrical and weather protection to hundreds of millions of solar panels across the globe, enabling aircraft cabin interiors to remain spotlessly clean flight after flight, to cladding iconic buildings around the world such as the Sheraton Hotel in Paris, Logan International Airport in Boston and protecting the myriad skylights over Wembley stadium in London, Tedlar film has demonstrated its superior protection in an envious list of applications for decades.”

Tedlar film provides superior protection against the elements, high-traffic, and touch surfaces; it is chemically-inert, resistant to cleaning with harsh chemicals, to dirt, corrosion, the effects of prolonged exposure to UV radiation and does not support the growth of mold, mildew and other fungi. Tedlar is specified in almost all commercial aircraft interiors, exceeding stringent U.S. Federal Aviation Administration requirements for toxicity and flammability; it is also used in photovoltaics where Tedlar film for backsheets has been demonstrated in the field to protect solar modules for over 35 years.

The history of Tedlar began in 1901 when vinyl fluoride was first synthesized by Belgian chemist Frederic Swarts. Four decades later, in 1942, polyvinyl fluoride was invented by DuPont, with the company being granted a U.S. patent for the process of polymerization in 1947. In 1961, DuPont received the original registered trademark for Tedlar PVF film and officially introduced it for commercial use. Two years later, in 1963, Boeing first used Tedlar film for its aircraft interiors.

By the early '70s, Japan had begun using Tedlar film for highway noise barriers. In 1986, after an 11-year study sponsored by the U.S. Department of Energy, NASA’s Jet Propulsion Laboratory qualifies Tedlar film for backsheets, due to its long-term performance attributes. NASA’s Phoenix Mars Lander used Tedlar PVF film as part of its bio barrier in 2007, and in 2012, the largest-solar powered boat with Tedlar-protected photovoltaic panels sails around the world.

“But rather than focusing on the past, we are resolutely turned towards the future, and the numerous new possibilities Tedlar film has to offer, such as in healthcare interiors for its ability to withstand cleaning with harsh chemicals or in bifacial photovoltaics where its lightweight and durable properties make it ideal for installing larger-size, higher power-producing panels," Wang said.

Today, DuPont Tedlar PVF film is trusted around the globe as the high-performance asset protection standard. DuPont continues to develop new Tedlar-based applications to meet evolving marketplace needs, including innovative films for use in flexible, building-integrated solar power, greenhouses, vehicle-integrated photovoltaics, as well as backsheet repair solutions for damaged solar panels in the field.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!