Roofing Safety

Latest Innovations in Active and Passive Fall Protection for Roofers

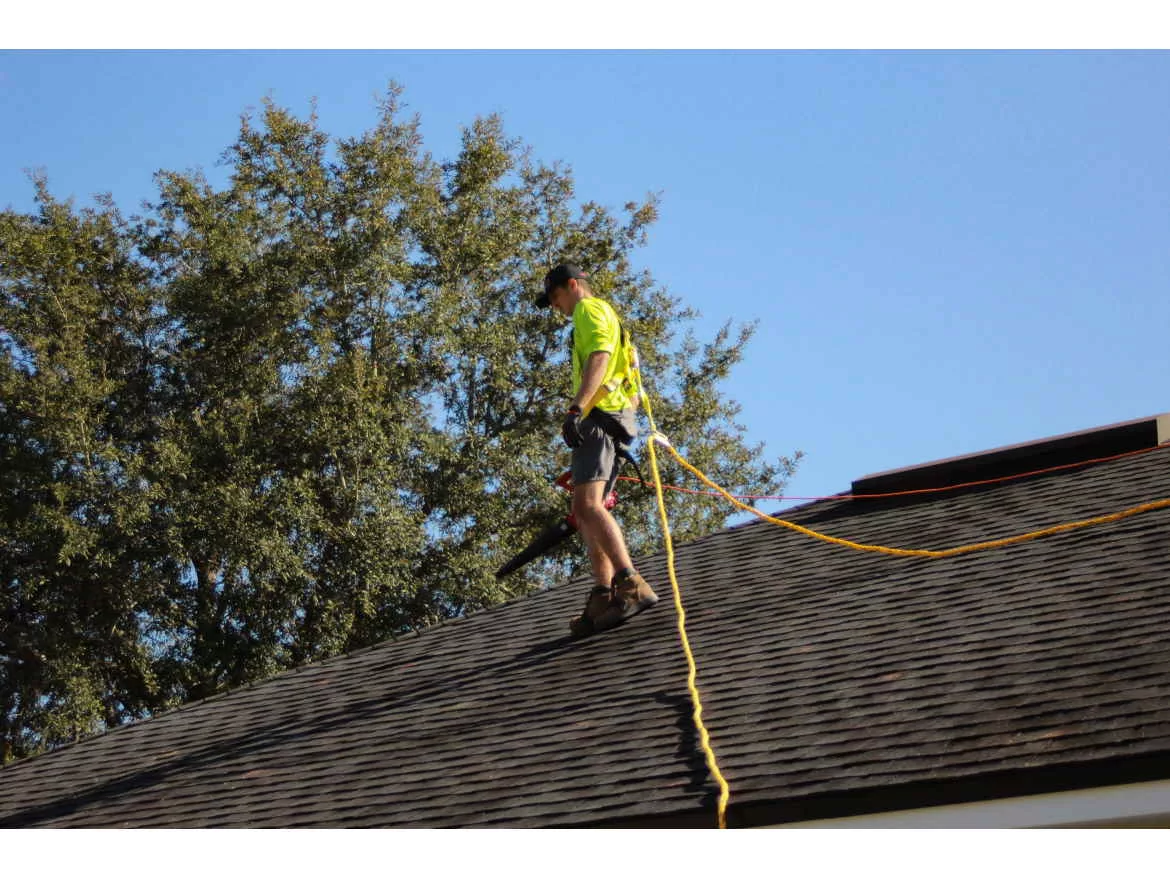

Roofing remains dangerous work, but new products and technologies emphasizing the latest regulatory requirements emerge.

In the ever-evolving landscape of occupational safety, fall protection systems have been a critical focus area in roofing safety. Over the years, these systems have undergone significant transformations to provide robust and effective safety measures for those working at heights. Different products and technologies have emerged while emphasizing the latest regulatory requirements. Read on as we explore some examples of these products.

Prioritizing Safety on the Roof

Navigating the complexities of occupational safety, particularly fall protection, involves a structured approach known as the 'hierarchy of controls.' This system, visualized as a pyramid, prioritizes the most effective strategies for hazard control:

- Elimination: The top of the pyramid and most effective measure involves removing the hazard entirely, such as redesigning work processes to avoid working at heights.

- Substitution: Next is replacing a dangerous process with a safer one, like using telecommunication tools instead of climbing towers.

- Engineering Controls: If elimination or substitution aren't possible, physical modifications to the workplace, like installing guardrails or fall arrest systems, are employed.

- Administrative Controls: Changes in work policies or schedules to reduce fall risk, such as limiting time spent at dangerous heights or enforcing safety protocols.

- Personal Protective Equipment (PPE): The final line of defense is PPE like harnesses or helmets, providing personal protection without removing the hazard.

Innovating to Navigate the Regulatory Landscape

The intricate world of fall protection revolves around the need for consistent innovation and adherence to evolving regulatory requirements. Key among these standards are those outlined by the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). Fall protection systems in roofing works must be designed to meet the requirements of ANSI Z359.16 as well as OSHA 1910.140 and 1926.502.

The ANSI Z359.16 standard is an integral part of the ANSI Z359 Fall Protection Code. It specifically addresses the safety requirements for climbing ladder fall arrest systems, providing a comprehensive set of guidelines on system performance, testing, and labeling. It ensures that these systems are not only capable of preventing falls but also able to minimize injury if a fall were to occur.

On the other hand, OSHA's standards 1910.140 and 1926.502 are cornerstones of its guidelines for personal fall protection systems. The former applies to general industry workplaces and lays out the criteria for personal fall arrest systems, travel restraint systems, and positioning systems. The latter, applicable to construction work, addresses the requirements for fall protection in several construction operations.

Fall Protection Advancements in Roofing Work Sites

Through the years, different fall protection systems have been introduced. Below are examples of innovations from edgefallprotection.com that are worth looking at when promoting roofing safety.

Active Fall Protection

The Fall Arrest Ladder Safety System is exemplary when it comes to active fall protection that meets the stringent requirements of the new ANSI Z359.16 standard, as well as OSHA 1910.140 and 1926.502. The design allows it to accommodate two users simultaneously on a fixed ladder, offering a high degree of adaptability and safety. This system utilizes detachable cable sleeves, ensuring optimal user mobility and safety. The system's flexibility is another key feature, as the mounting brackets can be utilized on a variety of fixed ladder styles. This adaptability makes it a versatile choice for different working environments. Furthermore, it offers a 100% tie-off capability through an integrated fall arrest anchor point on the top bracket, rated at 3,600 lbs. This feature allows for continuous connection, enhancing user safety during ascent or descent.

Another leading-edge example of active fall protection systems is EDGEFallProtection’s Ranger Mobile Anchor fall restraint system, which can be conveniently relocated across diverse work sites and settings. What sets it apart is its counterweighted base with a 360-degree rotating arm, enabling the anchorage point to be positioned directly above the worker for optimal fall arrest and restraint. More so, it has a capacity of up to 310 pounds and is extendable up to 18, 20, and 22 feet. This system adheres to OSHA's fall protection codes and the specific requirements of ANSI Z359.6 for the design and performance of active fall arrest systems, exemplifying its rigorous commitment to safety regulations.

Passive Fall Protection

Standing seam metal rooftops present some challenges especially when they get slippery after rain. Advancements are most welcome. One that stands out is EDGE Fall Protection’s AccuFit Standing Seam Metal Roof Guardrail, which is designed to help those who need to ensure OSHA compliance in metal rooftops without penetrating the roof. The system uses S5 Clamps to attach to the existing roof seams and can be fully tightened with stainless steel set screws. This creates a fully compliant standing seam roof guardrail system that is quick and easy to install.

To comply with OSHA regulations for roof guardrail installation on corrugated or R Panel rooftops, EDGE makes use of self-drilling technology screws and self-sealing gaskets. This method ensures that the installation process is both simple and leak-free.

Other Advanced Fall Protection Measures in the Roofing Industry

The sphere of roofing safety has seen a surge in innovative measures to bolster both active and passive fall protection. Key among these is the integration of IoT technology into smart Personal Protective Equipment (PPE). Harnesses equipped with IoT devices, for instance, can instantly alert supervisors if a worker falls, thus reducing response times and potentially saving lives.

Drone technology has also marked a significant shift in how roof inspections are carried out. By utilizing drones equipped with high-resolution cameras and thermal imaging technology, potential risks such as leaks or structural weaknesses can be detected without exposing workers to fall hazards.

An equally impressive innovation is the development of modular guardrail systems. Unlike traditional fixed guardrails, these systems offer a combination of flexibility and robust protection. They can be quickly assembled, disassembled, and reconfigured to fit different roof shapes and sizes, making them an excellent solution for varied and complex roofing projects. This adaptability, coupled with their steadfast commitment to worker safety, makes them a true testament to the continuous evolution of fall protection in the roofing industry.