Roofing Contractor's Editor's Choice 2018: Roofing Products and Innovations

New Roofing Products and Innovations that Caught our Eye for 2018

Carlisle’s RapidLock.

The family of KnuckleHead accessories and adhesive sealant from Green Link.

The HyperLite SumoStance by Little Giant Ladders.

Eric Velliquette, vice president of sales and marketing for Lakeside Construction Fasteners, received the Best New Product Award at IRE 2018 for the LCF COR-10 WOODX.

LEAP Software App.

SOPREMA Sure-Stick™.

Roofing Contractor shares their Editor's Choice of the products and innovations the roofing industry has to offer in 2018.

Old habits are hard to break, so again Roofing Contractor’s editors spent much of the annual show-season scouring the show floors for exhibitors with new and innovative products to help improve efficiency on the rooftop, back at the office, or in the truck somewhere in between. Here’s our comprehensive list of the favorite products we saw over the past 12 months that should become part of your arsenal to win and complete more jobs.

The selections are based on criteria that factors in ingenuity and innovation, problem-solving, and potential market impact. While assigning value to the following products is subjective, we hope the information educates roofing contractors and starts an open and free-flowing debate about the top tools and best services the industry has to offer. Here are our Editor’s Choice honorees for 2018.

Editor's Choice

• Tools • Safety • Innovations • New Technology

LCF COR-10 WOODX • Lakeside Construction Fasteners

Lakeside Construction Fasteners had people talking on the 2018 International Roofing Expo show floor in New Orleans with its LCF COR-10 WOODX. The new high-strength fastener is engineered to secure corten metal panels into hardwood decking substrates, offers a sealed protective barrier, and comes pre-weathered for exact corten metal panel color match.

Roofing contractors will no longer need to wait for fasteners to be painted or weathered to match corten metal panels. The panel of roofing industry experts named it the best new product at the 2018 IRE.

“This is really an honor,” said Eric Velliquette, vice president of sales and marketing for Lakeside Construction Fasteners, moments after receiving the award from show officials. “We always look forward to exhibiting our new and innovative products at this show and introducing them to the metal roofing market.”

The low-maintenance tool has high-low threads and a sharp T-17 cut point that allows the fastener to quickly penetrate the corten metal panel for quicker, low-cost installation. It can also be used with battery operated screw guns including Impact Screw Guns.

3-4 B/D Vent • Lifetime Tool & Building Products

Lifetime Tool® followed up last year’s success at the IRE 2017 with the Ultimate Pipe Flashing® by focusing on new bath and dryer vents in New Orleans. The developers said they considered all of the design and performance failures inside and out that have plagued roof vents — and their installers — for decades, and set out to completely address them.

They started with the basic plate, increasing its size generously to work without any caulk, sealants, or underlayments. Then they moved to water-tight-forever proprietary vent attachments to the plate, along with fire-retardant PVC elements that are designed to provide extreme wind-driven rain performance while addressing everything from damper noise to condensation.

All exterior components are 24ga Kynar® coated Galvanized exhibiting exceptional performance. The shingle vent is available in dark brown while the one specifically developed for metal roofing will be available in several Kynar colors. Both have easily removable caps for any necessary maintenance.

Included with each vent is a sturdy snap-in screen and a 3” to 4” no-glue adapter — all the roofing contractor needs in one box.

Ergo Stripper • Tie Down Engineering

Roofing can be back-breaking work, but it doesn’t have to be. The product developers at Tie Down Engineering think so too, and brought their latest innovation for shingle and other roof debris removal to the 2018 IRE. The Ergo Stripper is designed to alleviate the back and neck pain roofing contractors often develop while crouching, ducking and balancing on dangerous slopes to do shingle tear offs and repairs. It’s built for contractors standing between 5’ and 6’-3” and equipped with an arm holster and comfortable handles to take pressure off of the back muscle groups.

Using an athletic stance — standing with knees bent and a straight back, roofing contractors can use their knees and thighs to do the heavy lifting, allowing their body weight to become the lever exerting the force needed to strip a rooftop. The stance allows them to maximize their strength and speed, as the Ergo Stripper can complete a tear off 20-percent faster than traditional methods.

Miller® Falcon™ Edge SRL • Honeywell

Honeywell launched a new line of premium, durable self-retracting lifelines designed to help roofing crews avoid fatalities and serious injuries if their line is damaged or severed by a sharp edge during a fall.

The new Miller® Falcon™ Edge SRL series is specifically designed to protect workers who are tying off at foot level or working near sharp edges by ensuring the lifeline remains intact if a fall were to occur over an edge.

Honeywell researchers estimate that as many as 80 percent of fall protection applications have the potential for the lifeline to come in contact with an edge in the event of a fall.

“Traditional self-retracting lifelines have not been designed to perform against sharp edges, and run the risk of being severed or otherwise compromised,” said Leah Shook, fall protection product marketing manager for Honeywell Industrial Safety.

Available in 20-, 30- and 50-foot cable lengths, the Miller® Falcon™ Edge SRL provides versatility, reliability, and maximum safety. It’s effective for at-height work situations with the capacity to support user weights up to 420-lbs. in all connections at foot level and above, including horizontal, vertical and overhead mounting.

All Miller® Falcon™ Edge SRLs meet the most stringent safety requirements including those of the ANSI-Z359.14 Class B & LE standards, and include a galvanized steel cable lifeline with carabiner, tagline and integrated shock absorber. Models featuring a flame-retardant shock absorber cover are available for welding applications.

SHOWA 4561 Glove • SHOWA

Kevlar® has been saving lives of police officers on the streets and soldiers on the battlefield for decades, and now it’s finding its place in roofing.

One of the latest innovations in hand coverings for roofing contractors was introduced by SHOWA and partner DuPont at the National Safety Council Congress and Expo (NSC) in Indianapolis last fall. The SHOWA 4561 Glove is engineered with Kevlar, which makes it cut resistant on the rooftop.

In addition to its ANSI A4 ranking, the SHOWA® 4561 utilizes SHOWA’s patented Zorb-IT® grip technology, allowing users to maintain a stronger grip in oily and wet conditions without sacrificing safety. The top of the glove showcases a new informational design that indicates the glove size, the Zorb-IT®technology, genuine Kevlar® logo, and the glove’s certifications. To maximize dexterity, the SHOWA® 4561 is creatively engineered with next generation seamless fit technology which allows for better comfort along the fingers and palm.

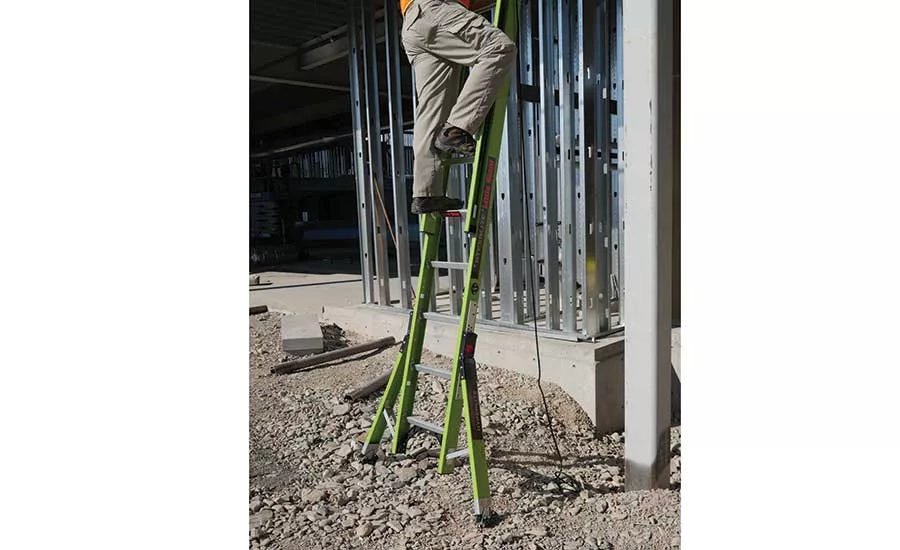

Hyperlite SumoStance • Little Giant Ladders

Also attracting a fair amount of attention at the NSC was the HyperLite SumoStance® fiberglass extension ladders. Developed by Utah-based Little Giant Ladders, the SumoStance improves the safety of roofing contractors by tripling the base width of the ladder and by increasing its side-tip stability. It also claims to be the lightest Type IA and IAA fiberglass extension ladder in the world, weighing up to 40 percent less than typical fiberglass ladders used by contractors worldwide.

Little Giant designed the breakthrough innovations featured in the new HyperLite and HyperLite SumoStance ladders to overcome common ladder accidents, including injuries caused by the weight of the ladder and injuries caused by overreaching. These types of accidents often result in lost work time and can vary in severity of injury, from strains and sprains to death.

“Traditional extension ladders are a major risk for professionals and safety inspectors,” said H. Arthur Wing, chairman and president. “The HyperLite sets a new standard in ladder safety and provides a safe experience for professionals who use extension ladders, while reducing risk.”

KnuckleHead Accessories • Green Link

Green Link introduced a family of custom-engineered, molded straps and caps for securing pipes and struts for its KnuckleHead rooftop support product line. The straps are designed for both heavy pipe and strut support KnuckleHeads, while a cap design was developed for lite pipe supports. All are molded from tough, weatherproof urethane and are a striking yellow color to emphasize safety.

Pipe supports are attached with standard stainless-steel sheet metal screws, which are supplied with the heads. The Strut Support straps are available in nominal pipe sizes ranging from ¼" to 6".

Custom straps are available by special order. These elastomeric straps slide into the strut channel and snap in place, eliminating the need for screws.

“There is growing interest in securing rooftop mechanical installations in the face of high wind conditions and seismic events,” said Ondrej Pekarovic, Green Link design engineer. “These straps will greatly increase the stability of pipes, conduit, channel and related mechanical equipment.”

Green Link also introduced a new adhesive/sealant designed for use with its KnuckleHead Rooftop Support System. The Green Link Adhesive/Sealant bonds and seals the KnuckleHead Universal Base and is effective on a wide range of roof surfaces. The new adhesive/sealant has been specially formulated to adhere to PVC, EPDM, TPO, and Mod Bit, as well as the KnuckleHead base itself, which is composed of glass-reinforced nylon.

“The KnuckleHead base is unique in that it can be adhered directly to the roof membrane,” Pekarovic explained.

“While there are some products on the market that effectively bond and seal the KnuckleHead base, Green Link Adhesive/Sealant is the only product that effectively adheres to even the most challenging types of PVC membranes.”

The sealant is based on polyether chemistry. It cures by exposure to moisture, so it can be applied to damp surfaces and will not shrink upon curing. It will not discolor from UV exposure, can be applied at temperatures as low as 32°F, and is capable of joint movement in excess of 35 percent. It is available in standard 10.1oz cartridges.

SURE-STICK • SOPREMA

Ohio-based SOPREMA launched a company-record six new products in 2018, including SURE-STICK™, its first self-adhered roofing membrane product line. The family consists of four new products that are designed to be more user-friendly and provide roofing contractors an odorless application that saves time, labor and materials on a wide range of commercial roofing installations.

SURE-STICK™ Nail Base — an SBS-modified anchor sheet for use over nailable substrates, such as wood decking.

ELASTOPHENE SURE-STICK™ — a glass-fiber-reinforced product with a film surface that allows installers to eliminate priming when installing the cap sheet, reducing labor and material costs.

SOPRALENE SURE-STICK™ — a similar, polyester-reinforced product with a film surface that also allows installers to eliminate priming when installing the cap sheet, reducing labor and material costs.

ELASTOPHENE SURE-STICK™ FR GR — a fire-retardant cap sheet product with a granulated surface that features a side lap film and a split-back release film underneath that makes application easier.

All SURE-STICK self-adhered products feature a specially formulated underside compound designed for reliable application, even at low temperatures. The SURE-STICK cap membrane also includes a special side lap film, which protects the side lap and ensures maximum adhesion.

“As self-adhered products that do not require priming, SURE-STICK membranes can be used even in sensitive applications like schools, hospitals and other occupied structures without disruption,” explained Matt Davis, product manager for SOPREMA. “We designed these products as an extension to our existing self-adhered line to be as user-and bystander-friendly as possible while saving our customers money in the process.”

RapidLock • Carlisle Construction Materials

Velcro as a roofing material component in residential applications made some waves at the IRE 2017 in Las Vegas. But it became part of the buzz at and following IRE 2018, where it was introduced as the main component of the latest membrane enhancement from Carlisle Construction Materials.

Carlisle officials touted its new RapidLock Technology as a revolutionary step in efficiency and time-savings for commercial roofing contractors when they unveiled it at the IRE 2018. This adhesive-less system uses Velcro® Brand Securable Solutions to fully attach 115-mil FleeceBACK® RL EPDM or FleeceBACK RL TPO to InsulBase® RL or SecurShield® HD RL Polyiso insulation.

Contractors benefit from no temperature restrictions, making winter installations part of a work schedule. The adhesive-less system means less time on the roof for the initial install, and maintenance since it rated strongly for wind uplift and hail resistance.

“Everyone in the industry is worried about labor and really the only thing holding roofing contractors back this year will be having the bandwidth to get jobs done,” explained Mike DuCharme, vice president of marketing for Carlisle Construction Materials. “This opens up that bandwidth because it’s going to go on so fast. You’re not going to have to wait 30 minutes for glue to dry or wait for the outdoor temperature to improve.”

The RapidLock system left an impression on the show floor, taking the award for best commercial product.

“We’re very excited about this product, seeing that it’s an industry first — a fully-adhered system that’s adhesiveless,” said Chad Buhrman, Carlisle’s insulation product manager.

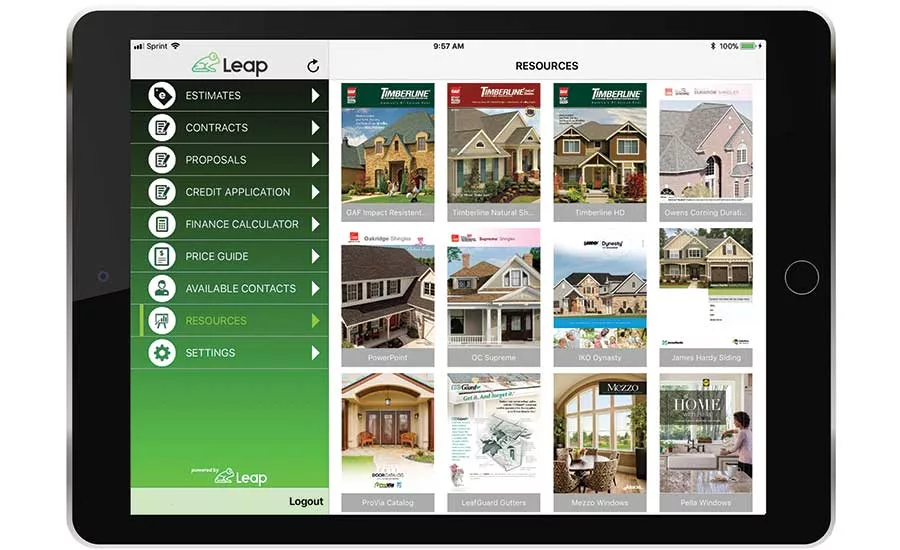

Leap

With technology becoming an ever-increasingly important part of a roofing contractor’s day-to-day — regardless of company size and capability — it’s no surprise that the business and technology pavilion at the 2018 IRE was the largest it had been in recent years in terms of exhibitors and interest. Among the new companies making its roofing industry debut was Leap. Based in Baltimore, Leap is a software company that launched a new mobile app developed by a roofing salesman who believes the technology has the potential to change how roofing contractors handle the in-home selling process.

It helps roofing contractors and their customers by simplifying, securing and automating the day-to-day sales process for all stakeholders. The app alleviates costs for home services companies by digitizing the all-paper sales process and eliminating inaccurate measurements.

“I got tired of the cumbersome paperwork and dated processes, and when I developed and started using the Leap application, I knew that this software would be a game-changer for our industry,” said Leap creator and CTO Steve Stencil.

Leap also provides a digital library of company resources available to homeowners at any time, and can shorten the sales process and training that’s essential for every contractor to build revenue.

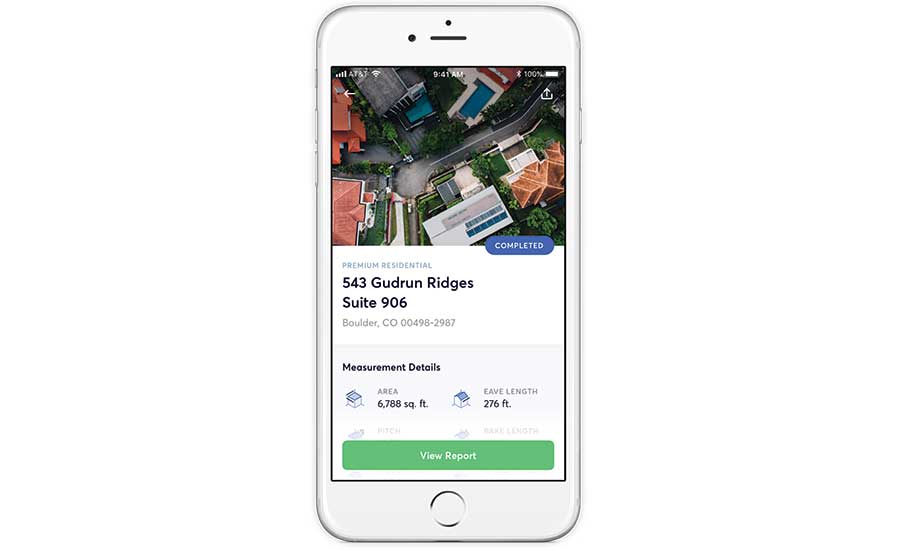

EagleView Mobile App • EagleView Technologies

EagleView Technologies launched a new mobile app for roofing contractors that allows them to see key measurements quickly, introduces a new dashboard for report access and status updates, and provides the ability to upload user-generated images.

The latest innovation utilizes EagleView’s vast library of more than 350 million aerial images to provide contractors with accurate measurements at-a-glance, and instant access to their data and reports anytime, anywhere.

EagleView’s own high-resolution images of the property are used to produce a detailed report, which is rapidly delivered to the app. Contractors preparing bids can now upload user-generated images from their phone to track their jobs and include in the EagleView report. It also allows contractors to share files on any device and access them at any time in one place.

“From the clean, easy-to-use interface to the ability to quickly access reports on the go, the EagleView app is going to dramatically improve workflows and make the bidding process a faster, smoother experience for all involved,” said Rishi Daga, EagleView CEO.

Users can download the EagleView app at the iTunes App Store today. An Android version is planned for release later this year.

HOVER Now • HOVER

HOVER launched early last year and introduced its new customizable 3-D model for roofing contractors just before the 2017 IRE in Las Vegas. The app transforms smartphone photos of any home into a fully-measured, 3-D model that helps customers visualize the completed project and gives roofing contractors added accuracy when estimating materials needed to do the job. The product launched with two features — HOVER Connect and HOVER Prospect — and immediately made an impact for tech-savvy roofers looking to distinguish themselves from the competition.

Developers from the San Francisco-based software company didn’t rest on their laurels and continued to innovate with an idea to enhance the way roofing contractors sold jobs with nearly real-time features that allow them to customize bids and orders right from the homeowner’s kitchen table.

HOVER Now launched shortly after the 2018 IRE in New Orleans, where some roofing contractors got a taste of the newest feature that provides a roof squares estimate within 30 minutes — allowing contractors to pull together a quote while still onsite with the homeowner.

“HOVER Now’s quick turnaround time is impressive,” said Carl Holt, general manager at the St. Louis Branch of Erie Construction. “We can now double check our quote on the spot and close the deal. It’s a game changer for our business.”

Major companies both in and outside the roofing industry are taking notice, too. The company secured $25 million in Series B funding from investors that include GAF and the Home Depot.

With a simple interface and in-depth design features, HOVER is allowing contractors to provide homeowners with a comprehensive platform to visualize what their new roof or exterior remodeling project will look like — and transforming how home improvement projects are estimated and sold.

RhinoBond Hand Welder • OMG Roofing Products

OMG Roofing Products unveiled its latest enhancement to one of its signature products earlier this year called the RhinoBond Hand Welder. Based on patented Sinch® Technology, the portable hand welder is designed to help roofers weld RhinoBond Plates in those hard-to-reach spaces on the rooftop.

Tight spaces such as under raised rooftop HVAC equipment and piping and vertical surfaces have proved to be a challenge for roofing contractors trying to seal off the membrane. The hand welder is about the size of a typical hand iron, weighs just six pounds and is ergonomically designed to handle those tasks. The base is recessed and features centering indicator lines to help users properly align the tool over installed RhinoBond Plates for optimum bonding and improved productivity. It also features a vibrating handle and an indicator light when the tool is activate, and to alert roofers when the weld cycle is complete.

Company officials said some of their clients that have become loyal RhinoBond users have seen productivity jump 30 percent since adding the tool to the jobsite.

“To enhance the (RhinoBond) systems’ overall productivity, we wanted to offer a solution that can be used everywhere on the roof, even in tight spaces. This new product makes that possible,” said Web Shaffer, vice president of marketing for OMG Roofing Products.

AccuDRYve™ Compression Sensing Fastening System • Atlas Bolt & Screw

The AccuDRYve™ Compression Sensing Fastening System is a new approach to addressing the problem of over or under driving fasteners on the rooftop — which ultimately leads to roof leaks and contractor callbacks. Current driving technology utilizes torque and relies heavily on skilled installers. It’s estimated that even experienced crews incorrectly seat fasteners at least 30 percent of the time. AccuDRYve™ technology automatically stops driving the fastener when the cupped washer properly deflects to a flat shape, ensuring 100 percent proper fastener seating. The ergonomic technology also eliminates the ‘triggering’ of the screw gun reducing installer fatigue.

Developers focused on common-sense innovations to create a system that automatically stops driving the fastener when it’s properly seated for a leak-proof seal. First, the washer is engineered to deflect when the correct amount of force is applied. Second, the dual-thread design with a coarse thread just under the head pushes the metal down to the wood substrate prior to seating. This prevents the metal from extruding up and insures that the metal panel is flush to the substrate before seating of the fastener.

AccuDRYve™ presents the first best opportunity for consistent leak proof fastener installations regardless of jobsite skill levels. “AccuDRYve™ provides the perfect seal by everybody every time,” said Craig Mohr, vice president of Atlas’ sales.

ProCertification • NRCA

It’s not a product in the typical sense. There’s no physical tool to grab, or advanced technological gizmo with features that will help a roof installation or repair project go more smoothly. Yet, we RC editors suspect that in 2018, roofing contractors from around the country will be hearing a lot about, and probably participating in the ProCertification Program offered by the National Roofing Contractors Association (NRCA).

The initiative marks an unprecedented attempt in North America’s roofing industry to solve the ongoing workforce shortage by developing skilled workers that can have their abilities certified in specific roofing, waterproofing and rooftop solar system disciplines. The program is being driven by NRCA CEO Reid Ribble, who pledged $15 million from the organization to jumpstart training this year.

The program has the potential to become the single-most transformational process in the history of roofing in North America, Ribble said, and the goals are simple:

Address the workforce shortage by making the industry appealing through a standardized curriculum and training;

Create a visible career path;

Elevate roofing contractors to the level of other trade professions that have been following national standards for decades.

“We cannot draw enough people into this trade, and there’s a whole bunch of reasons for that,” Ribble explained while introducing the initiative from the Best of Success conference stage in Tucson, Ariz., last fall. “One thing we do know is that if we make the industry more appealing from an education standpoint and made ourselves equal with the plumbers, electricians and other trades, we can make progress.”

The curriculum is in development and the first wave of training for future course instructors is under way at training facilities offered by the NRCA’s manufacturing and trade association partners. A formal rollout is planned for the fall.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!