Roofing Contractor's Editor's Choice 2016

The Year's Promising Products That Caught Our Eye

MetLoop CEO Jay Southerland describes the company’s sophisticated radar system.

RIDGEPRO’s First Man Up

Shredded Tire’s "Echo" is constructed with 96 percent recycled materials.

The first quarter of 2016 is squarely in the rear-view mirror, and some of the best products the industry has to offer roofing contractors were unveiled at some of the biggest trade shows in the business.

Keeping with Roofing Contractor’s long tradition, our editors compared notes and assembled the following collection of products worth singling out with our annual Editor’s Choice awards.

The nominees are selected from products that showcase what we believe are some of the industry’s most promising recent innovations that, in some cases, can revolutionize roofing for years to come. The companies featured below, and many others industry-wide, highlighted worthy products over the past 12 months. Assigning value to the following products is open to debate, but, hopefully, by the time you’re done reading, there’s little doubt why these unique offerings grabbed our attention. Here are our Editor’s Choice honorees for 2016.

NEW TECHNOLOGY

From the year’s first cycle of industry events — ranging from the International Home Builders Show through the International Roofing Expo (IRE) and the North East Roofing Contractors Association (NERCA) — it’s clear that 2016 is a particularly strong year for emerging technologies that have many different applications both inside and outside of roofing.

Win the Weather

Weather can make or break a roofing contractor’s year. Even if companies aren’t in the storm-repair market, having a few extra weeks of work given or taken away by unpredictable fluctuations in the seasons can really impact the bottom line. Knowing how to maximize — and monetize — Mother Nature takes persistence, flexibility and having the right information at the right time. And the best tools and technology in the business doesn’t hurt either.

MetLoop has created a new and unique approach to weather forecasting that can potentially put roofing contractors in the unfamiliar position of proactive lead generation and offering maintenance services before big storms hit. Using technology and hands-on expertise that, until now, was only available to the U.S. military, MetLoop is able to pinpoint areas, neighborhoods and even buildings in a storm’s path up to three hours in advance. The system then sends mobile alerts to the property owners, building managers and the roofing contractors that currently serve (or want to serve) them.

Based out of a technology-laden National Storm Damage Center in Ft. Walton Beach, Fla., the company processes data captured by sophisticated satellites also used by the National Weather Service, and filters it through software designed to predict weather for top-secret military missions and NASA exhibitions.

MetLoop also only hires retired or former meteorologists from nearby military bases that are trained to deliver highly-accurate forecasts and are Next-Generation Radar (NEXRAD) certified.

“We’ve put the power of the world’s most advanced weather technology in the hands of consumers, roofing contractors, manufacturers and distributors,” said CEO Jay Southerland. “We let them know exactly which homes and businesses are damaged in a storm and then we put contractors on the scene before anyone else.”

The company is the brainchild of Dave Carlson and Trevor Leeds — roofing contractors that revolutionized the industry when they developed EagleView Technologies and brought it to market. The duo say they’re back to change roofing again.

“We’re showing (roofing contractors) a way to utilize weather, manage their business and gain leads like no other way before,” said Leeds, MetLoop’s chief global strategist.

Visit MetLoop.com for more details.

Captured On Camera

Roofing contractors started using cameras to document roof conditions for bids and maintenance reports decades ago. Most good ones know they should be taking more photos to document their work and protect themselves from potential liability down the road.

But many of those same ones struggle with the technology or with developing a system to organize, store and maintain these potentially valuable resources for every job. The inventors of CompanyCam feel they have the answer.

CompanyCam is a user-friendly app that allows anyone on the roofing crew in the field or office to take photos that stream directly to a server that can be accessed by all stakeholders on a project in real time.

The app uses GPS to connect the photos with a real-world address or location and keeps them organized by that location so roofing contractors can easily find them when needed. Users can also draw or make notes that are then saved directly to an image that can be shared with others.

Previously, contractors needed to download photos from their smartphone or digital camera memory card to a computer, organize them, and then disseminate them to company leaders, facility managers and building owners. With CompanyCam, there are no lengthy uploading procedures, no renaming or copying files, and no need to create separate accounts on photo-sharing websites or systems.

“We’re taking what roofing contractors intuitively know they need to do and building a system that’s simpler and fits into the contractor’s work flow,” said Luke Hansen, company founder.

Hansen said the app formally launched last fall and is gaining momentum in the roofing industry following a strong showing at the IRE 2016 in Orlando. It’s also proving to be very useful for companies in other fields, such as insurance, home improvement and property management. Find more information at www.companycam.com.

Get the Visual

You’ve likely all been there. You’ve satisfied the prospective customer’s objections on price, put them at ease about roof life and warranty longevity, and demonstrated your company’s expertise when compared to competitors in your market. Then, they ask “What will it look like?” and if you’re not careful here, you could be back to square one.

iRoofing may have the solution with its Roof Visualizer. This new roof simulator allows roofing contractors to demonstrate how the roof they’d like to install will look on the prospect’s home regardless of which manufacturer they choose for materials. Specifically, the visualizer:

- Offers full customization, allowing the contractor to scale product size, roof pitch and shading to provide a comprehensive preview.

- Allows for side-by-side comparisons of roofing and siding to help attain that ‘perfect’ look.

- Replaces the need for hauling samples up a ladder to the roof, or sending customers on seeing-eye scout visits to similar installations in your town or the next one over.

The system is easily integrated into iRoofing’s mobile software platform — which is designed to improve a contractor’s presentation skills and sales success. Users can easily create the best presentation for their customers, increase their closing percentage, and constantly access the most current catalogs, brochures and literature.

It also provides a big lift for companies concerned about differentiation in a crowded marketplace. By taking actual photos of a house and enhancing them with a virtual roof created with the products they selected, there’s not much to leave to the customer’s imagination.

When a customer fears making the wrong decision, a tool like the Visualizer can put any concerns about curb appeal to rest. For more information, visit iroofing.org.

Phones and Drones

Getting a comprehensive view of a roof using real-time video images can be a huge time saver and differentiator for roofing contractors in any market.

VantedgePoint offers a host of solutions for roofing contractors looking to improve overall efficiency by using real-time video images to craft estimates with the highest degree of accuracy. VideoSurv is backed by drone technology that interfaces with software exclusively designed to capture and store images in the cloud. VantedgePoint is also taking digital measuring to a whole new level.

The videos can be captured with smartphones, drones or most typical handheld video cameras, and the innovative programming produces measurements that can be viewed and used on any iOS device.

Perhaps the best part is that contractors benefit from the use of drone technology without paying any of the start-up costs; no need to invest in a drone or worry about becoming a licensed drone pilot with all the requirements under current FAA regulations. VantedgePoint is partnering with Drone Base to offer contractors real-time video images taken by professional drone pilots. More information is available at www.vantedgepoint.com.

3-D Roofing

Many roofing contractors would argue that there’s no replacement for stepping on the roof and seeing conditions for themselves. Yet, they’d still like to save time and become more efficient when estimating or specifying a job. Product developers at GAF recently launched an innovative digital tool to help contractors do just that. The E360 3-D Visualizer and Estimator is a free downloadable app that allows roofing contractors to create detailed reports of a home.

Contractors can download the free app on either their Android or iOS systems. Users then take a minimum of eight pictures around the home’s perimeter, and the app guides the contractor to help frame the photos appropriately. The photos are then uploaded to the cloud, and in less than 24 hours, the app creates an unobstructed 3-D rendering of the home, complete with measurements of the roof, siding, and windows.

Each report costs a nominal fee — and even less if contractors want just the roof measurements without the siding and windows.

Other benefits include more accurate pricing with actual roof measurements, and 3-D modeling allows for savings on materials and work hours as less time is needed for hands-on measuring. The roof measurements include key areas like square footage, ridges, valleys, eaves, and rakes for a very comprehensive report.

The GAF E360 app is available in the Apple Store or Google Play by searching GAF. See more information in the blog section at GAF.com.

SAFETY

First Man Up

Baseball has its leadoff hitter, orchestras have their conductor, and first responders have a dispatcher — key individuals who possess a particular skill that sets the stage for others to do their jobs well. In roofing, they’re known as the ‘first man up,’ and since they’re literally the first person on the roof to inspect and establish safety conditions for others, there aren’t many pieces of safety equipment that have the potential to limit their risk of injury…or worse.

Until now.

The RIDGEPRO™ system offers faster access to the peak of steep-sloped roofs and is a lightweight alternative to roof planks or scaffolding. It’s extremely well constructed, easy to assemble and intuitive to use. While also sold in a standard package, the RIDGEPRO™ PLUS kit comes complete with:

- A double-wheel-mounted, aluminum ridge anchor (7 lbs.), adjustable up to 12:12 pitch gable roofs attached to pole using threaded fitting with safety clip.

- A 16-foot-long telescoping, fiberglass pole with snap clips to attach to anchor (a 24-foot-long, 3-section painter’s pole may be substituted for longer pitches).

The RIDGEPRO™ is affordable and ready to install right out of the box.

A complete fall protection system should never unnecessarily penetrate the roof’s water proofing, or be too difficult for a single worker to install, use and dismantle without additional roof top assistance. The tool must also be designed for its intended purpose and removed from service immediately without harm to others after any event that could impact its structural integrity.

The RIDGEPRO™ meets almost all of the above design criteria, as it’s designed for 6/12 to 12/12 pitch roofs.

And the inventor — longtime roofing contractor Brian Strawder — isn’t done yet. The manufacturer is currently working on a variety of design improvements and attachments, including a bearing plate designed to conform to most metal roof profiles. Visit theridgepro.com to learn more.

Standing Seam Roof Anchor

Once crewmembers get on the roof, they’ll need the proper anchoring system to help keep them up there. The Standing Seam Roof Anchor 1 (SSRA1), is a new product that could revolutionize how homeowners, building owners, and roofing contractors conceptualize safe working conditions atop standing seam roofs.

For starters, it allows crews to work safely on standing seam roofs without penetrating the panels. The patented, non-penetrating design consists of a solid 6061-T6 aluminum body with 12 stainless steel set screws.

It’s engineered for a universal fit with roughly 500 standing seam panel profiles, and contractors need not worry about replacing their existing equipment from a compatibility standpoint. The interchangeable mount allows for attachment of devices from various fall protection manufacturers.

The standard assembly also includes a d-ring for single-man attachment certified for up to 5,000 lbs. The d-ring is also attached on a swivel, allowing work on both sides of the roof without having to reset the anchor.

The SSRA1 is ready to use as a single-seam, single-user anchor with no assembly required. It’s built with non-corrosive aluminum and stainless steel components, and can be powder coated to color match roofs for permanent installations.

Judges at the 2016 IRE awarded it second place in the Product Showcase competition. It’s also proudly made in U.S.A. with a “lifetime life-saving warranty.”

Penetrator Mobile Fall Protection Cart

We all know the age old saying, “Safety first,” and the roofing industry is a prime example of a business where the motto needs to stand true. Arguably the most important safety aspect for roofers is fall protection, which has come a long way for workers on jobsites over the past few years. The Penetrator Mobile Fall Protection Cart from Tie Down Engineering takes fall protection one step further.

The first of its kind, this product is not only lightweight, but also fully portable. The sharp spikes pierce the roof insulation and metal decking when a fall occurs on the jobsite, creating an anchor. Tested for use on all different types of roofing systems including TPO, ISO, PVC and EPDM — and OSHA compliant — the penetrator provides fall restraint for a total of five workers. Three can be tied off using the fall arrest connection mechanism with corresponding attachment points, and an additional two workers can use the remaining attachment points. Made in the U.S.A, the penetrator comes equipped with a cart that features flat free tires, and a locking steering column that can withstand up to 2,000 lbs.

It took third place honors from judges at the 2016 IRE Product Showcase competition. For more information, visit www.tiedown.com.

LIVING GREEN

Rubber Retreads

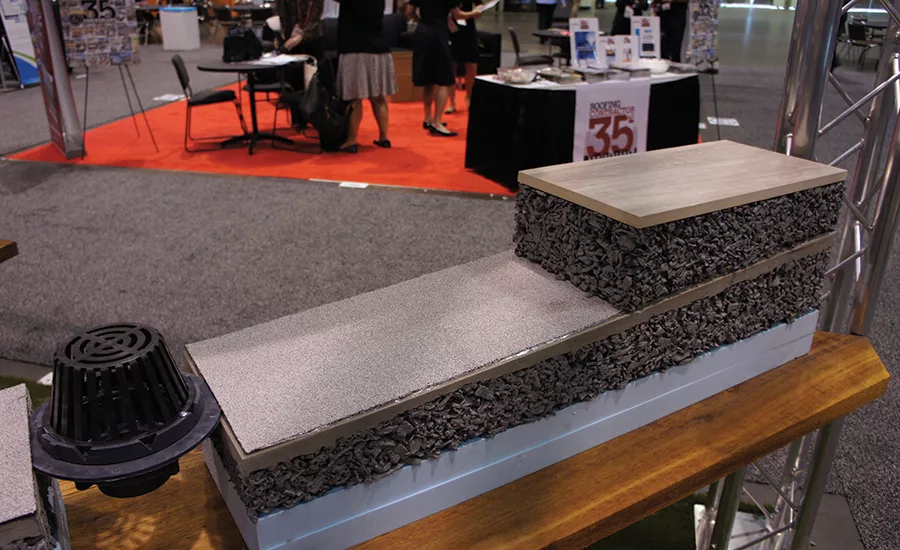

As recycling and sustainability methods grow in popularity throughout the roofing industry, so do the number of products that are produced with environmental consciousness in mind. Roofing professionals are consistently searching for new product innovations that can provide functionality, defense against the elements, and provide additional relief on the environment. Shredded Tire has constructed a unique product that aids in environmental conservation called Echo.

According to Recycle Nation, an estimated 300 million tires are thrown away annually in the United States. Developed over many years of research, Echo provides customers with high strength and insulation, while being helpful toward the environment. Constructed with 96 percent recycled materials, this product is specifically designed to take old tires — an abundant resource that is not biodegradable — and repurpose them for use in roofing systems.

Echo aims to eradicate the issues connected with traditional roofing systems — namely the environmentally toxic material that is used to construct them — and has the ability to remain functional even while wet. The product’s tested uplift strength of -937PSF is unparalleled for a product of its kind in the industry. In addition to providing LEED credits, Echo presents its users with infinite opportunities for environments such as green roofs and rooftop golf courses. To learn more, visit shreddedtire.com.

COMMON PROBLEMS, NEW SOLUTIONS

Panel Curver

Awarded “Best New Product” at the 2016 IRE, the Curver from D.I. Roof Seamers is a panel curving machine used for bending a panel radius on common snap-lock metal roof panels with a narrow batten cap. Producing convex-only curves, this unique product is extremely user friendly and modifies with ease. In addition to the Curver, D.I. Roof Seamers offers a wide variety of additional products that can be rented and shipped directly to the job site. For more information, visit diroofseamers.com.

Smart Vent

It’s no secret that roofing systems are complex. Experienced professionals recognize that each individual system has its own unique design, where all aspects of said system work together for proper functionality and protection. A very important component of these systems includes proper ventilation techniques. Inadequacies in roof ventilation can result in a number of problems down the line including ice dams, rust, mold and more.

The SmartVent from DCI Products provides the customer with state of the art attic ventilation practically anywhere it’s needed on the roof. Using ridge and soffit venting, the Smart Vent allows for colder air to enter under the shingle, creating accurate attic cooling and greater air flow throughout. There are many potential benefits to the SmartVent, including possible extension of the life of your asphalt shingles, as well as lowered utility expenses, specifically in summer months. The SmartVent is extremely versatile and can be installed in various imperative places on the roof, based on both where the ventilation is needed, as well as customer preference. This multi-purpose vent can be used on a wide assortment of roof shingles including asphalt, cedar, slate, tile and even metal. To further service the customer, the company’s website features a ventilation calculator where customers can go and determine their required amount of ventilation. To learn more, visit dciproducts.com.

Getting a Grip

Metal panels, by nature, are heavy, cumbersome and difficult to move safely — all factors that impact a roofing contractor’s productivity goals and workmanship.

Enabling the power of vacuum force to lift, guide and move them across measurable distances has the Wood’s Power Grip positioned to be a potential time saver and added safety precaution on the jobsite.

Flexible rubber vacuum pads attach securely to metals and claddings, and each attach directly to the face of the panel, which keeps edges free for precise placement. There’s also no need for hooks that can damage the panels and slow down installation.

For roofing contractors, the quick attachment and release process means improved productivity, and the ergonomic design helps reduce the potential for fatigue and injuries traditionally associated with repetitive movements.

The vacuum technology also applies to larger-sized panels that need to be lifted by crane to the roof. In many cases, riskier, more labor-intensive methods such as slings, ropes and pulley systems could become things of the past.

Whether in the warehouse or on the jobsite, panel handling can be faster, easier and likely much safer when the hand-held vacuum cups and below-the-hook vacuum lifters are used properly. The full line of Wood’s Power Grip products come with detailed maintenance instructions for each specific model that include testing and inspection schedules. Customers can also seek help from authorized dealers and the factory’s technical service specialists for repairs or issues that are not covered in the instructions. Vist www.wpg.com for more details.

Stealth Approach

Traditional 5V Crimp metal roofing panels have been around a long time and have always been installed the same way — through-panel fastening. StealthBond© offers a new way of doing it without hundreds, if not thousands, of fastener penetrations through the metal.

This very innovative approach to a proven metal roofing system utilizes a high-strength structural adhesive that creates a permanent bond while concealed underneath. Not only does it provide for a cleaner look, but installs faster than traditional 5V Crimp roofs and cuts down on production time because the adhesive eliminates the need for pre-drilling screw holes.

It also minimizes dimpling effects of oil canning, and the adhesive stays flexible, allowing for the natural expansion and contraction of the metal roofing panels. That helps make it ideal for the residential and light commercial markets.

Each installation is carefully designed and custom crafted by qualified metal roofing contractors that achieve certification as StealthBond© dealers and installers. Cost depends on multiple variables — including region and complexity of the project, but the StealthBond© is priced similarly to a typical concealed-fastener system.

The product is approved under the Florida Building Code and is recorded with the U.S. Patent and Trademark Office. It’s manufactured in America and backed by Gibraltar Industries, a leading international manufacturer and distributor of building products.

It’s encouraging to see so many companies developing and improving some of the most interesting, innovative and progressive products taking the roofing industry forward. With continued focus and investment in research, sustainability, workforce efficiency and safety, we’re already looking forward to seeing the next wave of game-changing products in development for 2017 … but we’ll just have to wait.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!