Technical Details: Recent Changes to Building Codes Relating to Roofing

Recent changes to roofing materials, application methods and destructive weather events have combined to create changes to roof-related items in the building codes. Prior to 2000, there were three main building codes recognized and adopted throughout the United States.

Recent changes to roofing materials, application methods and destructive weather events have combined to create changes to roof-related items in the building codes. Prior to 2000, there were three main building codes recognized and adopted throughout the United States. They were Building Officials and Code Administrators International (BOCA), International Conference of Building Officials (ICBO) and Southern Building Code Congress International (SBCCI). The plethora of codes made enforcement and compliance confusing because municipalities within the same state would often adopt different codes.

Recent changes to roofing materials, application methods and destructive weather events have combined to create changes to roof-related items in the building codes. Prior to 2000, there were three main building codes recognized and adopted throughout the United States. They were Building Officials and Code Administrators International (BOCA), International Conference of Building Officials (ICBO) and Southern Building Code Congress International (SBCCI). The plethora of codes made enforcement and compliance confusing because municipalities within the same state would often adopt different codes.

In 1997, these three code agencies formed the International Code Council (ICC) in an effort to draft a standard set of regulations that were consistent and inclusive of each other for ease of enforcement. In 2000, the ICC’s efforts to standardize several separate building codes resulted in the formation of the International Building Code (IBC), which has been adopted by most municipalities in the United States. The IBC is the basis for this article. Contractors must check with their local authorities to stay informed on all local code variances required for roof compliance. Section 15 of the IBC Code refers to “Roofs and Roof Structures.”

Addition of Roof Materials

The advent of new materials and systems has resulted in changes to the roof codes. The primary change has been the addition of several new materials and application methods. The code defines the required testing for approved materials and application methods - including the required roof slopes - for application of these materials:

1507.2 Asphalt shingles

1507.3 Clay and concrete tile

1507.4 Metal roof panels

1507.5 Metal roof shingles

1507.6 Mineral-surfaced roll roofing

1507.7 Slate shingles

1507.8 Wood shingles

1507.9 Wood shakes

1507.10 Built-up roofs

1507.11 Modified bitumen roofing

1507.12 Thermoset single-ply roofing

1507.13 Thermoplastic single-ply roofing

1507.14 Sprayed polyurethane foam roofing

Edge Metal Flashings and ANSI/SPRI ES-1

Edge Metal Flashings and ANSI/SPRI ES-1

Section 1504.5, “Edge Securement for Low-Slope Roofs,” reads as follows: “Low-slope membrane roof system metal edge securement, except gutters, shall be designed and installed for wind loads in accordance with Chapter 16 and tested for resistance in accordance with ANSI/SPRI ES-1, except the basic wind speed shall be determined from Figure 1609.”

The intent of the code is to ensure that the design and installation of roof edge metals and copings meet specific criteria including material specifications, wind resistance of the edge metal and the structural integrity of the substrate that anchors the edge metal (such as nailers, etc.). The key elements considered in determining the loads on the roof edge are:

• Wind speed.

• Occupancy.

• Building height.

• Location of the edge material.

• Building location.

ES-1 Test Methods

There are three test methods required under ANSI/SPRI ES-1. They are:

1. RE-1: “Roof Edge Termination Test.”

2. RE-2: “Pull-Off Test for Metal Edge Flashing.”

3. RE-3: “Pull-Off Test for Metal Wall Coping.”

The metal system applied at roof edges and wall copings must pass these tests for ES-1 certification. Thee test methods as defined by the standard are completed in the following manners.

RE-1 tests the roof edge termination for mechanically attached and ballasted roofing systems. The RE-1 test evaluates the perimeter attachment to ensure that it meets a minimum holding power of 100 pounds per foot. The membrane is pulled at a 45-degree angle to the roof deck to simulate a billowing membrane. Failure is defined as any event that allows the membrane to come free of the edge termination or the termination to come free.

The RE-2 test is a pull-off test for metal edge flashing. It evaluates the strength of the metal edge flashing to ensure that the fascia system meets or exceeds the building’s calculated design wind pressure. A load is applied to the fascia metal, simulating wind load on the fascia. The calculation used is: Force at failure x face = blow-off resistance. The results must meet or exceed the calculated design pressure of the building.

RE-3 is a pull-off test for metal wall coping. It evaluates the strength of the metal coping cap to ensure that it meets or exceeds the building’s calculated design wind pressure. A load is applied to the coping cap, simulating wind load. Simultaneous up and out forces are used. The calculations used to determine the blow-off resistance for the top, face leg and back leg are: Force at failure x surface area = blow-off resistance.The results must meet or exceed the calculated design pressure of the building.

For roofing contractors, the code eliminates shop (or field) fabrication of metal edge flashings and metal copings in municipalities that that have adopted ANSI/SPRI ES-1. (At this time, most states and many municipalities have adopted the code. Best practice is to check local codes for all projects.)

For designers, it implies that perimeter edge calculations and wind engineering are required to determine the perimeter edge design pressure. Design of perimeter edge and metal copings should be in compliance with ANSI/SPRI ES-1.

For metal edge manufacturers, the code requires approved testing and certification of all metal edge flashings and metal copings. Manufacturers that do not meet the compliance standards of ANSI/SPRI ES-1 will not be allowed on facilities in municipalities that have adopted the code.

Attachment of Asphalt Shingles

Attachment of Asphalt Shingles

Section 1504.1.1, “Wind Resistance of Asphalt Shingles” states: “Asphalt shingles shall be installed in accordance with Section 1507.2.7. For roofs located where the basic wind speed in accordance with Figure 1609 is 100 mph or greater, asphalt shingles shall be tested in accordance with ASTM D 3161, Class F. As an alternative, load and wind resistance of asphalt shingle roof coverings shall be determined in accordance with Section 1609.5.2.”

In high-velocity wind zones, asphalt shingle application requirements are as follows. Fasteners used should be 11/4-inch No. 12 wire gauge shank nails with a 3/8-inch diameter head. A six-nail pattern is required at each shingle.

Placement of fasteners is as follows:

• Three-tab shingle: below self-sealing tar line

• Dimensional shingles: within nailing zone

With roof cement application, apply three 1-inch diameter dabs at each shingle and two dabs at rakes, hips and ridges.

Use of Aggregate

Section 1504.8, “Gravel and Stone,” reads: “Gravel or stone shall not be used on the roof of a building located in a hurricane-prone region as defined in Section 1609.2, or on and other building with a roof mean height exceeding that permitted by Table 1504.8 based on the exposure category and basic wind speed at the building site.”

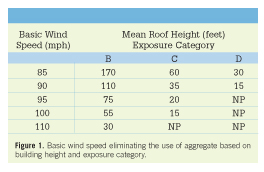

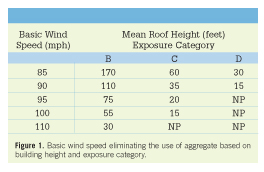

This code eliminates the use of aggregate in high-velocity wind zones. The table in Figure 1 provides the basic wind speed that eliminates the use of aggregate based on the building height.

Roof Removal Requirements

Section 1510.3, “Recovering Versus Replacement,” states that new roof coverings shall not be installed without first removing all existing layers of roof coverings where any of the following conditions occur:

1.Where the existing roof or roof covering is water soaked or has been deteriorated to the point that the existing roof or roof covering is not adequate as a base for additional roofing.

2.Where the existing roof covering is wood shake, slate, clay, cement or asbestos-cement tile.

3.Where the existing roof has two or more applications of any type of roof covering.

Upcoming Code Changes

There are two new IBC code changes that will have an impact on the roofing industry that are set to become effective with the next code revision. There will be a revision to 1504.5, “Edge Securement for Low-Slope Roofs” to include the testing of gutters. Until this time, testing of gutters has been excluded from the code. The other code change that is being discussed is for the wind-uplift and fire testing of garden assemblies. This code will be implemented when testing procedures are defined.

Changes to ASHRAE Standard 90.1

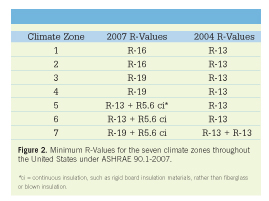

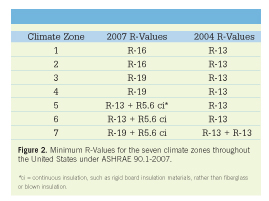

ASHRAE has recently increased the minimum insulating values required for roofs and walls. In the 2007 edition of ASHRAE 90.1-2007, “Energy Standard for Buildings Except Low-Rise Residential Buildings,” Addendum “g” provides the minimum R-Values for the seven climate zones throughout the United States. The data is contained in Figure 2. (Please note that zones 5, 6 and 7 represent the coldest climate zones.)

It should be noted that these are standards and not codes. However, most codes reference ASHRAE as compliance requirements, so best practice is to check local codes for all projects.

In 1997, these three code agencies formed the International Code Council (ICC) in an effort to draft a standard set of regulations that were consistent and inclusive of each other for ease of enforcement. In 2000, the ICC’s efforts to standardize several separate building codes resulted in the formation of the International Building Code (IBC), which has been adopted by most municipalities in the United States. The IBC is the basis for this article. Contractors must check with their local authorities to stay informed on all local code variances required for roof compliance. Section 15 of the IBC Code refers to “Roofs and Roof Structures.”

Addition of Roof Materials

The advent of new materials and systems has resulted in changes to the roof codes. The primary change has been the addition of several new materials and application methods. The code defines the required testing for approved materials and application methods - including the required roof slopes - for application of these materials:

1507.2 Asphalt shingles

1507.3 Clay and concrete tile

1507.4 Metal roof panels

1507.5 Metal roof shingles

1507.6 Mineral-surfaced roll roofing

1507.7 Slate shingles

1507.8 Wood shingles

1507.9 Wood shakes

1507.10 Built-up roofs

1507.11 Modified bitumen roofing

1507.12 Thermoset single-ply roofing

1507.13 Thermoplastic single-ply roofing

1507.14 Sprayed polyurethane foam roofing

Figure 1: Basic wind speed eliminating the use of aggregate based on building height and exposure category.

Section 1504.5, “Edge Securement for Low-Slope Roofs,” reads as follows: “Low-slope membrane roof system metal edge securement, except gutters, shall be designed and installed for wind loads in accordance with Chapter 16 and tested for resistance in accordance with ANSI/SPRI ES-1, except the basic wind speed shall be determined from Figure 1609.”

The intent of the code is to ensure that the design and installation of roof edge metals and copings meet specific criteria including material specifications, wind resistance of the edge metal and the structural integrity of the substrate that anchors the edge metal (such as nailers, etc.). The key elements considered in determining the loads on the roof edge are:

• Wind speed.

• Occupancy.

• Building height.

• Location of the edge material.

• Building location.

ES-1 Test Methods

There are three test methods required under ANSI/SPRI ES-1. They are:

1. RE-1: “Roof Edge Termination Test.”

2. RE-2: “Pull-Off Test for Metal Edge Flashing.”

3. RE-3: “Pull-Off Test for Metal Wall Coping.”

The metal system applied at roof edges and wall copings must pass these tests for ES-1 certification. Thee test methods as defined by the standard are completed in the following manners.

RE-1 tests the roof edge termination for mechanically attached and ballasted roofing systems. The RE-1 test evaluates the perimeter attachment to ensure that it meets a minimum holding power of 100 pounds per foot. The membrane is pulled at a 45-degree angle to the roof deck to simulate a billowing membrane. Failure is defined as any event that allows the membrane to come free of the edge termination or the termination to come free.

The RE-2 test is a pull-off test for metal edge flashing. It evaluates the strength of the metal edge flashing to ensure that the fascia system meets or exceeds the building’s calculated design wind pressure. A load is applied to the fascia metal, simulating wind load on the fascia. The calculation used is: Force at failure x face = blow-off resistance. The results must meet or exceed the calculated design pressure of the building.

RE-3 is a pull-off test for metal wall coping. It evaluates the strength of the metal coping cap to ensure that it meets or exceeds the building’s calculated design wind pressure. A load is applied to the coping cap, simulating wind load. Simultaneous up and out forces are used. The calculations used to determine the blow-off resistance for the top, face leg and back leg are: Force at failure x surface area = blow-off resistance.The results must meet or exceed the calculated design pressure of the building.

For roofing contractors, the code eliminates shop (or field) fabrication of metal edge flashings and metal copings in municipalities that that have adopted ANSI/SPRI ES-1. (At this time, most states and many municipalities have adopted the code. Best practice is to check local codes for all projects.)

For designers, it implies that perimeter edge calculations and wind engineering are required to determine the perimeter edge design pressure. Design of perimeter edge and metal copings should be in compliance with ANSI/SPRI ES-1.

For metal edge manufacturers, the code requires approved testing and certification of all metal edge flashings and metal copings. Manufacturers that do not meet the compliance standards of ANSI/SPRI ES-1 will not be allowed on facilities in municipalities that have adopted the code.

Figure 2: Minimum R-Values for the seven climate zones throughout the United States under ASHRAE 90.1-2007.

Section 1504.1.1, “Wind Resistance of Asphalt Shingles” states: “Asphalt shingles shall be installed in accordance with Section 1507.2.7. For roofs located where the basic wind speed in accordance with Figure 1609 is 100 mph or greater, asphalt shingles shall be tested in accordance with ASTM D 3161, Class F. As an alternative, load and wind resistance of asphalt shingle roof coverings shall be determined in accordance with Section 1609.5.2.”

In high-velocity wind zones, asphalt shingle application requirements are as follows. Fasteners used should be 11/4-inch No. 12 wire gauge shank nails with a 3/8-inch diameter head. A six-nail pattern is required at each shingle.

Placement of fasteners is as follows:

• Three-tab shingle: below self-sealing tar line

• Dimensional shingles: within nailing zone

With roof cement application, apply three 1-inch diameter dabs at each shingle and two dabs at rakes, hips and ridges.

Use of Aggregate

Section 1504.8, “Gravel and Stone,” reads: “Gravel or stone shall not be used on the roof of a building located in a hurricane-prone region as defined in Section 1609.2, or on and other building with a roof mean height exceeding that permitted by Table 1504.8 based on the exposure category and basic wind speed at the building site.”

This code eliminates the use of aggregate in high-velocity wind zones. The table in Figure 1 provides the basic wind speed that eliminates the use of aggregate based on the building height.

Roof Removal Requirements

Section 1510.3, “Recovering Versus Replacement,” states that new roof coverings shall not be installed without first removing all existing layers of roof coverings where any of the following conditions occur:

1.Where the existing roof or roof covering is water soaked or has been deteriorated to the point that the existing roof or roof covering is not adequate as a base for additional roofing.

2.Where the existing roof covering is wood shake, slate, clay, cement or asbestos-cement tile.

3.Where the existing roof has two or more applications of any type of roof covering.

Upcoming Code Changes

There are two new IBC code changes that will have an impact on the roofing industry that are set to become effective with the next code revision. There will be a revision to 1504.5, “Edge Securement for Low-Slope Roofs” to include the testing of gutters. Until this time, testing of gutters has been excluded from the code. The other code change that is being discussed is for the wind-uplift and fire testing of garden assemblies. This code will be implemented when testing procedures are defined.

Changes to ASHRAE Standard 90.1

ASHRAE has recently increased the minimum insulating values required for roofs and walls. In the 2007 edition of ASHRAE 90.1-2007, “Energy Standard for Buildings Except Low-Rise Residential Buildings,” Addendum “g” provides the minimum R-Values for the seven climate zones throughout the United States. The data is contained in Figure 2. (Please note that zones 5, 6 and 7 represent the coldest climate zones.)

It should be noted that these are standards and not codes. However, most codes reference ASHRAE as compliance requirements, so best practice is to check local codes for all projects.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!