FAA Grants Tremco SkyBEAM Nighttime Drone Commercial Flights

The FAA Loosens Regulations on Flights to Help Locate Energy Leaks, Rooftop Damage and Other Issues

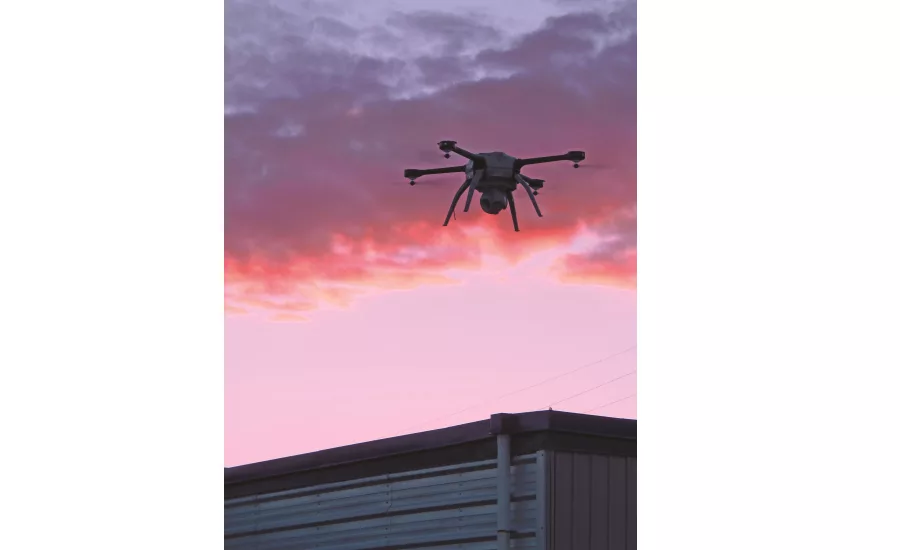

Photo courtesy of Tremco Roofing.

As predicted by many industry experts in and around the roofing industry, 2016 is indeed proving to be a significant time in the development of drone use for commercial purposes. And roofing contractors around the United States may start benefiting from it very soon, according to company officials at Tremco Roofing and Building Maintenance.

In April, Tremco’s SkyBEAM unmanned aerial vehicles (UAVs) received the first-ever approval for nighttime commercial drone operation over United States soil from the Federal Aviation Administration (FAA). Regulators also approved the Beachwood, Ohio-company’s request to operate UAVs during the day.

“We didn’t get everything we wanted, but we’re thrilled for night flights to be the launching point for this cutting-edge technology,” said Robb Chauvin, Tremco’s executive director for inspection services. “It’s going to be for the greater good of the roofing industry.”

Flights could begin before the end of the year, and contractors may begin to realize the savings in time and resources, experts say.

The Sky’s the Limit

Their optimism surrounds the SkyBEAM UAV’s vast capabilities.

The groundbreaking SkyBEAM (Building Envelope Aerial Mapping) UAV flies around buildings and uses high-definition (HD) video and thermographic (infrared) cameras to locate where there may be energy leaks, rooftop damage, deteriorating facades, safety issues and other potential problems.

SkyBEAM’s thermographic camera shows temperature variations around a building that indicate problems — such as poor or missing window sealing or wet rooftop insulation — that can lead to significant capital expenses, increased operating costs, occupant discomfort and other issues.

Infrared scanning is most effective at night, when the sun is not warming the building. Traditional infrared scans require technicians to traverse rooftops at night, while facade inspections dictate working from scaffolding or cranes. SkyBEAM is safer, faster, more cost effective and more accurate than conventional methods of mapping buildings.

In addition to its infrared scanning capability, SkyBEAM has an exceptionally high resolution video camera that can easily read the fine print on a warranty from 50 feet. This camera can map potential building problems, such as gaps or tears in the roof, tiny cracks or movement in the facade, deteriorating concrete and the need for appropriate rooftop safety equipment.

“We program the UAV to fly to a precise height, do the mapping and return. We can now map buildings without the time and expense of using tools such as scaffolding,” said Paul Sheehy, Tremco’s vice president of sales. “SkyBEAM enables us to find problems for our customers that would have been virtually impossible to detect before, and without risking people’s safety.”

Technicians can then safely mark problem areas during the day for removal and replacement, or further analysis.

How it Works

Toronto-based Industrial SkyWorks (ISW), a leader in aerial building inspections using unmanned technologies, developed SkyBEAM in partnership with Tremco Roofing. For the past 18 months, ISW operated SkyBEAM drones in Canada with great success, officials said. The FAA has approved ISW to operate SkyBEAM commercially in the U.S. and it’s available to Tremco customers through their exclusive relationship with ISW.

A highly trained two-person crew, including a licensed pilot, operates the UAV safely on the ground. SkyBEAM can fly horizontally across roofs, or vertically up to 400 feet (approximately 40 stories). It can reach speeds of 25 mph and retain its flight path in winds of up to 25 mph and gusts reaching 50 mph.

Officials said it’s ideal for low-slope roofing and facade diagnostics on multi-building campuses such as educational institutions and healthcare facilities. It’s also supported by the more than 200 Tremco Roofing sales representatives across the country, as well as more than 600 field technicians in Tremco’s WTI (Weatherproofing Technologies Inc.) subsidiary.

Facade inspection ordinances have become increasingly common as cities such as New York, Chicago and numerous others seek to ensure public safety.

Interactive reporting clearly shows the building’s condition. SkyBEAM’s software consolidates infrared scans and HD video images into a comprehensive, interactive, easy-to-understand report that facility owners, managers and technicians access through a cloud-based application. The report clearly and accurately shows problem areas, helping decision makers determine their plan of action.

A virtual model of the building is created in 2D and 3D and can be viewed from any angle. The model allows users to overlay thermal images to their exact location on the building. Photographs, comments and other data can be added in real time through a tablet to ensure that work can be verified and that reports are updated with the latest information.

Data can also be transmitted down to those on the roof. Through geo-positioning, technicians can always see their exact location in relation to problem areas. As they walk across the roof, the scan moves with them so they can locate precisely where work needs to take place.

“We are extremely pleased with the FAA’s support to help address this growing regulatory need,” Sheehy said. “SkyBEAM provides a dramatic leap forward, improving safety, efficiency and analysis. We look forward to working with the FAA, our industry partners and building owners to make further improvements to the facade inspection process.”

From the success that SkyBEAM has seen in Canada, Sheehy believes it will revolutionize the industry.

“There is nothing like SkyBEAM, and we’re delighted to bring its many benefits to our customers in the U.S.,” he said. “It gives decision makers visual evidence of where their building is losing energy, especially from areas that were difficult to scan before. SkyBEAM will help them improve their facility maintenance planning and budgeting, is the safest way to conduct nighttime infrared scanning, and is a huge benefit to our field technicians and contractors who need to locate and repair rooftop and facade damage.”

One Small Step . . .

Other industry leaders said moving beyond daylight flights is the real benefit to the roofing contractor from the FAA’s recent decision, and that they will be watching the program’s progress closely.

“The requirement of daylight-only operations would severely limit the ability to capture critical data types,” noted Charles Mondello, president of the Property Drone Consortium (PDC). The PDC is comprised of leaders from the insurance industry, construction trades and several support enterprises dedicated to promoting further research and developing reasonable regulations for UAS use in commercial settings. Currently, only those with a pilot’s license or a Rule 333 exemption from the FAA can operate them.

“There is a strong benefit to the public and for the environment in energy savings and roof condition assessment,” Mondello continued. “Limiting UAS operations to daylight would result in continued use of other means at night, including humans on the roof to perform the same capture, increasing the risk to human life due to a fall.”

The safety benefit also stretches into areas affected by severe weather and natural disasters as the ability to fly at night enables operators to more quickly cover additional properties, and assist large groups of people in need of help.

The PDC believes that nighttime operations can be utilized and still maintain the same level of safety provided appropriate measures are taken. Those measures could include identifying potential obstructions such as power lines and cables prior to the mission, officials said. In addition, there could be greater separation between the target being inspected and the UAS flight. Additional requirements would include adequate navigation lighting, anti-collision lights and N-number illumination.

The real potential savings are in the preventative measures the UAV flights can generate.

Chauvin said he envisions facility managers and company executives using the data captured by UAVs in the boardroom to help make the case for capital improvements or preventative maintenance. As an asset management tool, it allows them to take stock of all aspects of the facility so companies can prioritize their capital spend.

“It’s the do-nothing vs. preventative approach,” he explained. “We’ve taken a $1 spend and prevented the spend of $9 to fix a problem. That’s significant for property owners and it’s not just limited to roofing. The entire building envelope is in play here.”

Information for this report was provided by Tremco. For more, visit www.tremcoroofing.com.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!