Rock On

In the process of making roofing history, parts of ancient rock formations were manufactured into tiny granules that would spread success to a number of products and companies. It was 75 years ago when the Wausau plant of 3M shipped the first colored roofing granules, marking a new era in roofing.

It began with a mountain.

In the process of making roofing history, parts of ancient rock formations were manufactured into tiny granules that would spread success to a number of products and companies. It was 75 years ago when the Wausau plant of 3M shipped the first colored roofing granules, marking a new era in roofing. From the depths of the Great Depression, a company built a successful business using tiny granules to top a new kind of roofing material, providing protection and beauty of a higher level for the country’s homes.

“We’re very proud of our heritage in this business,” says Martyn Tiplady, vice president of the Industrial Mineral Products Division of 3M. “Nurturing and growing a manufacturing business this complex is a fantastic challenge. Looking back, it is remarkable to trace the path of our plant expansion beyond Wausau, Wisconsin.”

The growth of 3M closely parallels the expansion of middle class America. Its plants, material development and rainbow of colors are a reflection of how suburban homes with pitched roofs came to dominate the landscape. The tiny granules were witness to major developments in asphalt roofing and have become an integral component in the success of countless products.

“The residential housing boom that followed World War II sent the demand for colorful asphalt roofs soaring,” says Tim Worms, marketing manager for 3M IMPD. “It was the architectural design of the ranch-style home that made the roofing material much more important to the overall appearance of the home.”

Founded in 1902, Minnesota Mining and Manufacturing was a St. Paul-based regional producer of abrasives for use in products like sandpaper. William McKnight, who became president just before the stock market crash in 1929, didn’t waste time making his first acquisition, a competitor that was in dire financial straits. With the purchase came a mountain in nearby Wisconsin that contained an abundance of quartz.

McKnight challenged the company to come up with a strategy. One avenue might be providing protection and colors for new prepared asphalt membranes that mimicked wood shingles. Unfortunately, the quartz didn’t prevent the ultraviolet (UV) rays from degrading the asphalt, causing a number of roofing failures. According to Frank Klink, laboratory manager for 3M, geology took a back seat to geography when a staff geologist, Jack Brown, happened to find the perfect quarry only five miles away from the Wausau plant. “That was very lucky, and that quarry is still in operation today,” he states.

The greystone rock was perfect for making roofing granules since it would block UV rays as well as accept the new ceramic coating developed by staff chemist George Swenson. Roofing material manufacturers needed a uniform color that could hold up in a variety of environments throughout the United States. The granules were a success, and now manufacturers had a durable and predictable surface for asphalt shingles that would soon be rolling out all over the country. Choice became the mantra for a new generation of consumers as they could now select the color of their roofs.

“Some people preferred to have colors, but you were dependent upon the natural color of the minerals,” says Klink. “Our strength has always been taking something that’s a commodity and engineering value and performance into it.”

Such procedures have led to further innovations in granules. Beginning in 1950, the company tackled the age-old problem of dark streaks on roofs caused by organic colonies. The culprit, an algae called gloeocapsa magma, could be found naturally on limestone in coastal regions, but the growth on roofs was apparent throughout the United States, even in the company’s backyard of Minnesota. In 1970, 3M was awarded its first patent for insoluble copper compounds in the granules that would inhibit algae growth.

Soon enough, there were a lot of demands being placed on these little rocks. The company continued to enhance the algae resistance of granules, experimenting with copper, zinc and a combination of materials. In 1991, 3M offered granules with a 10-year warranty against algae growth. The product performed so well that by 2002 it had become one of the dozens of 3M products to carry the revered Scotchgard™ brand, doubling the warranty. Additional test decks were established in Miami and Seattle, in addition to real roof applications at Sun City, Fla. In fact, the project has achieved a bit of fame among the residents of the large Florida retirement community.

“The community loves us,” says Worms. “They think it’s great that 3M is down there testing the latest products.”

Working closely with shingle manufacturers, 3M offers Cool Roofing Granules as a feature for residential customers. In 2005, Elk Premium Building Products became the first shingle producer incorporating 3M’s heat reflective granules. With shingle producers eager to differentiate their products from competitors, the asphalt shingle has been transformed into a high-performing technology with some of the longest roof warranties in the industry.

“If you adjust for inflation over the last 20 years, you’ll notice that asphalt shingle prices have held steady while increasing performance,” says Klink. “It’s kind of a testament as to how the industry has taken cost out and provided a higher performing product.”

Innovation continues with the company’s Customer Service Center in downtown St. Paul. Located close to the old company headquarters, this small-scale shingle prototyping facility allows clients to rapidly develop the design of new products and produce small quantities for on-site testing. This method is often much quicker and inexpensive than taking a full production facility off line.

“Quality, service and innovation are the hallmarks that make us an excellent supplier of high-performing products,” says Tiplady. “We certainly hope that the brand name appeal of Scotchgard™ will resonate with more end users as they select roofing products in the future.”

Certainly the low-slope roofing sector can benefit from the many improvements to roofing granules. Whether it’s testing new blends or 20-year old shingles, 3M continues to stand behind the product that stands in front of the sun. With initiatives like California’s Title 24 mandating more energy savings from building exteriors, the company’s research will continue to squeeze even more performance from the original rock.

1932 Wausau, Wis.

1947 Little Rock, Ark.

1948 Corona, Calif.

1961 Belle Mead, N.J.

2002 Pittsboro, N.C.

1929 3M purchases a competitor, Wausau Abrasives, for $260,000. Company president William McKnight challenged the management and laboratory team: “What can you do to make a mountain of silica quartz profitable?”

1937 3M’s test deck is established in Houston.

1950 Company starts investigating black streaks on roofing.

1951 Customer Service Center opens in St. Paul.

1964 Professor A.J. Brook of the University of Minnesota identifies the dark streaks on roofs the algae gloeocapsa magma.

1970 Patent awarded for algae-resistant granules.

1991 Algae Block™ is introduced with a 10-year warranty.

2002 Algae-resistant system earn Scotchgard™ brand, now backed with a 20-year warranty.

2005 Cool Roofing Granules are introduced.

It began with a mountain.

In the process of making roofing history, parts of ancient rock formations were manufactured into tiny granules that would spread success to a number of products and companies. It was 75 years ago when the Wausau plant of 3M shipped the first colored roofing granules, marking a new era in roofing. From the depths of the Great Depression, a company built a successful business using tiny granules to top a new kind of roofing material, providing protection and beauty of a higher level for the country’s homes.

“We’re very proud of our heritage in this business,” says Martyn Tiplady, vice president of the Industrial Mineral Products Division of 3M. “Nurturing and growing a manufacturing business this complex is a fantastic challenge. Looking back, it is remarkable to trace the path of our plant expansion beyond Wausau, Wisconsin.”

The growth of 3M closely parallels the expansion of middle class America. Its plants, material development and rainbow of colors are a reflection of how suburban homes with pitched roofs came to dominate the landscape. The tiny granules were witness to major developments in asphalt roofing and have become an integral component in the success of countless products.

“The residential housing boom that followed World War II sent the demand for colorful asphalt roofs soaring,” says Tim Worms, marketing manager for 3M IMPD. “It was the architectural design of the ranch-style home that made the roofing material much more important to the overall appearance of the home.”

Archival photos from 3M’s Industrial Mineral Products Division provide a vintage look at Wausau quarry operations.

Against the Grain

At the turn of the century, there weren’t many choices for fabricated roofing materials available to homeowners. Tile, metal and slate were quality materials, but something was needed for many modest suburban homes being built for the emerging middle class. Adequate wood for roofing wasn’t available in many parts of the country. Asphalt and coal tar were excellent products in many applications, but the steep-sloped roofs needed a product that wouldn’t flow or melt and could withstand the sun’s rays for more than a few years. The pitch and gravel roofing system that was serving commercial roofs so well soon became the paradigm for a new kind of roofing that would eventually cover a country - or at least most of its homes.Founded in 1902, Minnesota Mining and Manufacturing was a St. Paul-based regional producer of abrasives for use in products like sandpaper. William McKnight, who became president just before the stock market crash in 1929, didn’t waste time making his first acquisition, a competitor that was in dire financial straits. With the purchase came a mountain in nearby Wisconsin that contained an abundance of quartz.

McKnight challenged the company to come up with a strategy. One avenue might be providing protection and colors for new prepared asphalt membranes that mimicked wood shingles. Unfortunately, the quartz didn’t prevent the ultraviolet (UV) rays from degrading the asphalt, causing a number of roofing failures. According to Frank Klink, laboratory manager for 3M, geology took a back seat to geography when a staff geologist, Jack Brown, happened to find the perfect quarry only five miles away from the Wausau plant. “That was very lucky, and that quarry is still in operation today,” he states.

The greystone rock was perfect for making roofing granules since it would block UV rays as well as accept the new ceramic coating developed by staff chemist George Swenson. Roofing material manufacturers needed a uniform color that could hold up in a variety of environments throughout the United States. The granules were a success, and now manufacturers had a durable and predictable surface for asphalt shingles that would soon be rolling out all over the country. Choice became the mantra for a new generation of consumers as they could now select the color of their roofs.

“Some people preferred to have colors, but you were dependent upon the natural color of the minerals,” says Klink. “Our strength has always been taking something that’s a commodity and engineering value and performance into it.”

Colorful Start

The ceramic colored granules were among the first innovations in what would become a long line of developments in shingle manufacturing. To better design materials that could withstand the elements, 3M established an outdoor test deck in Houston in 1937. This allowed shingle manufacturers to use stringent, real-world conditions to measure their products’ performance over time. A hallmark of 3M’s development, rigorous testing ensures a predictable end product that meets expectations.Such procedures have led to further innovations in granules. Beginning in 1950, the company tackled the age-old problem of dark streaks on roofs caused by organic colonies. The culprit, an algae called gloeocapsa magma, could be found naturally on limestone in coastal regions, but the growth on roofs was apparent throughout the United States, even in the company’s backyard of Minnesota. In 1970, 3M was awarded its first patent for insoluble copper compounds in the granules that would inhibit algae growth.

Soon enough, there were a lot of demands being placed on these little rocks. The company continued to enhance the algae resistance of granules, experimenting with copper, zinc and a combination of materials. In 1991, 3M offered granules with a 10-year warranty against algae growth. The product performed so well that by 2002 it had become one of the dozens of 3M products to carry the revered Scotchgard™ brand, doubling the warranty. Additional test decks were established in Miami and Seattle, in addition to real roof applications at Sun City, Fla. In fact, the project has achieved a bit of fame among the residents of the large Florida retirement community.

“The community loves us,” says Worms. “They think it’s great that 3M is down there testing the latest products.”

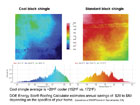

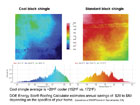

Thermographs of two identical-looking black shingles document the effectiveness of 3M’s Cool Roofing Granules.

Rock Is Cool

Another bonus of testing in the Sun Belt is a focus on the cost saving that can be achieved by reflecting more of the sun’s energy away from buildings. Cool roofing is another buzzword for energy-saving products that can reduce the heat load on buildings. When utilizing coloring agents that reflect more “near infrared heat” - which accounts for most of the heat build up in sunlight - cooling costs for some buildings can be reduced by as much as 20 percent. The white coatings common with commercial roofs wouldn’t pass muster with most homeowners, so 3M developed a way to provide the same rich or vivid colors consumers have always wanted but reflect much more of the sun’s heat.Working closely with shingle manufacturers, 3M offers Cool Roofing Granules as a feature for residential customers. In 2005, Elk Premium Building Products became the first shingle producer incorporating 3M’s heat reflective granules. With shingle producers eager to differentiate their products from competitors, the asphalt shingle has been transformed into a high-performing technology with some of the longest roof warranties in the industry.

“If you adjust for inflation over the last 20 years, you’ll notice that asphalt shingle prices have held steady while increasing performance,” says Klink. “It’s kind of a testament as to how the industry has taken cost out and provided a higher performing product.”

Innovation continues with the company’s Customer Service Center in downtown St. Paul. Located close to the old company headquarters, this small-scale shingle prototyping facility allows clients to rapidly develop the design of new products and produce small quantities for on-site testing. This method is often much quicker and inexpensive than taking a full production facility off line.

“Quality, service and innovation are the hallmarks that make us an excellent supplier of high-performing products,” says Tiplady. “We certainly hope that the brand name appeal of Scotchgard™ will resonate with more end users as they select roofing products in the future.”

Certainly the low-slope roofing sector can benefit from the many improvements to roofing granules. Whether it’s testing new blends or 20-year old shingles, 3M continues to stand behind the product that stands in front of the sun. With initiatives like California’s Title 24 mandating more energy savings from building exteriors, the company’s research will continue to squeeze even more performance from the original rock.

Sidebar: 3M's Rock Garden

The growth of 3M Industrial Mineral Products Division mirrored suburban growth patterns in the United States. The first plant expansion was, naturally, in Little Rock.1932 Wausau, Wis.

1947 Little Rock, Ark.

1948 Corona, Calif.

1961 Belle Mead, N.J.

2002 Pittsboro, N.C.

Sidebar:A 3M Timeline: 75 Years of Innovation

1902 Minnesota Mining and Manufacturing founded.1929 3M purchases a competitor, Wausau Abrasives, for $260,000. Company president William McKnight challenged the management and laboratory team: “What can you do to make a mountain of silica quartz profitable?”

1937 3M’s test deck is established in Houston.

1950 Company starts investigating black streaks on roofing.

1951 Customer Service Center opens in St. Paul.

1964 Professor A.J. Brook of the University of Minnesota identifies the dark streaks on roofs the algae gloeocapsa magma.

1970 Patent awarded for algae-resistant granules.

1991 Algae Block™ is introduced with a 10-year warranty.

2002 Algae-resistant system earn Scotchgard™ brand, now backed with a 20-year warranty.

2005 Cool Roofing Granules are introduced.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!