Between a Rock and a Hard Place

David Montross prides himself on his company’s ability to do it all. Montross, the President of Montross Weatherproofing Systems Inc. in Lake Forest, Calif., is a fourth-generation roofer.

David Montross prides himself on his company’s ability to do it all. Montross, the President of Montross Weatherproofing Systems Inc. in Lake Forest, Calif., is a fourth-generation roofer. He has an original proposal from his great grandfather dated Dec. 13, 1900, for a new roof, chimney and flashing - all for $65.

Of course, prices have risen since then, but Montross Weatherproofing still demonstrates an old-school commitment to quality work in both the commercial and residential markets.

“We’re unique,” Montross said. “We’re not just a roofing contractor. We’re a waterproofer, a deck coating contractor - we cover the entire building envelope, including below grade. We’re versatile. We do the little specialty things others can’t do. We can do additional projects for our customers, like waterproofing decks, pools, and fountains. We get our hands dirty and get things done.”

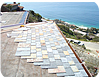

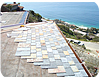

A recent project in Laguna Beach allowed Montross Weatherproofing to show off several of its skills in one setting. The custom home was built into a space carved into a mountainside just off the beach. Just excavating and stabilizing the site took the general contractor more than two years to complete.

A recent project in Laguna Beach allowed Montross Weatherproofing to show off several of its skills in one setting. The custom home was built into a space carved into a mountainside just off the beach. Just excavating and stabilizing the site took the general contractor more than two years to complete.

When it came time to install the roof, Montross was ready. The roof design included multiple levels that rise from 10 feet to 50 feet to match the surrounding topography. The homeowners wanted a slate roof with a section of solar panels, but after consulting with Montross they decided to install a slate roof in conjunction with a built-up, three-ply modified roof system from GAF Materials Corporation to accommodate the solar panels.

“For the solar roof section we were able to help re-engineer and put down a built-up modified roof,” said Montross. “We helped lay out the plan for the solar panels. We were able to influence the owner and architect to go to a more serviceable roof for that section.”

All of the materials were chosen to withstand the extreme conditions of the Pacific Coast. The slate was specifically chosen to withstand he the harsh environment. Fasteners were either stainless steel or copper, depending on the application, and copper was used for all the exposed metal, including the flashing, corbel wraps, gutters, spikes and ferrules. The metal was all done in house and fabricated on site. The company also waterproofed three main decks and various balcony decks.

The overriding philosophy for this job, according to Montross, was the same as any other: “Do it right the first time. You don’t want to go back.”

Numerous Challenges

Numerous Challenges

The fall start was problematic, and the schedule barely allowed enough room to complete the project before winter set in. Weather, scheduling the various crews, and coping with members of other trades were all key challenges on the project, but safety was always the greatest concern.

“The biggest challenge was fall protection,” said Montross. “We maintained safety lines on 10 or 12 different levels. Having retractable harnesses and lines was key. On one side you’d be down five feet to the deck; on the other side you’d be down 50 feet into the dirt.”

Approximately 95 percent of the 7,000 square feet of roof space was covered in slate. For the slate, the homeowners wanted a six-color blend, with equal amounts of each color randomly laid. “We were able to work with the owner to match their needs. It took a little more time, but we worked with the manufacturer. American Slate helped us out and packaged it that way. The customer is always right, right?”

The courses were laid to minimize foot traffic. “Slate is a very durable product when it comes to weathering, but walking on it and drilling through it can cause breakage,” Montross said. “We built in some additional material to allow for breakage, and we worked our way off the roof to minimize traffic on the slate.”

The courses were laid to minimize foot traffic. “Slate is a very durable product when it comes to weathering, but walking on it and drilling through it can cause breakage,” Montross said. “We built in some additional material to allow for breakage, and we worked our way off the roof to minimize traffic on the slate.”

Given the start date, they all knew weather could be a concern. “Sometimes the fog rolled in so thick you couldn’t even see,” he said. “It took us right off the project. And there were some rain days as well. So, you could say we had weather issues.”

Coordinating the work at each stage was crucial to meeting the schedule, and the company made sure the members of the built-up crew, shingle crew and sheet metal crew were all on the same page. “The key was getting the right crew out there at the right time,” Montross said. “We made sure we had the right guys doing the right scope. We aren’t trying to force a square peg into a round hole. Our crews are diversified, and there’s some overlap, but we always make sure our crews are doing the work they’re the most comfortable doing.”

Scheduling the various crews was difficult, but it worked smoothly, thanks to one of the company’s superintendents, Vinnie Palladino. “With a difficult job like this, you have to make sure each step is completed, and he made sure our crews were coordinated so we could keep the project rolling,” said Montross. “So, kudos to Vinnie.”

Scheduling the various crews was difficult, but it worked smoothly, thanks to one of the company’s superintendents, Vinnie Palladino. “With a difficult job like this, you have to make sure each step is completed, and he made sure our crews were coordinated so we could keep the project rolling,” said Montross. “So, kudos to Vinnie.”

The three members of the sheet metal crew did all the metal fabrication and installed all of the custom gutters. “These guys are true craftsmen. They have the eye. They can just look at the spot and make sure they can fit it perfectly.”

The tight schedule led to some problems caused by members of other trades. Crews sometimes found that window installers, painters doing touch-up work, and inspectors damaged tiles, but the slate crew promptly handled any replacements.

“The schedule given to us was very tight,” said Montross, looking back at the project. “The best-laid plans would’ve had a spring or early summer start. But we worked with the parameters given by the customers. The schedule was tough. In the end, it all worked out.”

“It was a nice little job,” he concluded. “It was unique. It had some scopes that were custom, so we were able to use the strengths of all of our different crews. There were challenges - weather, the time of year, problems with other trades - but all in all it went very well. The customer had the resources to design a better system, and we were able to work with him and make suggestions to make sure he got what he wanted.”

This custom home in Laguna Beach was built into the cliffside. The roof features multiple levels that rise from 10 feet to 50 feet to match the surrounding topography. (Photos courtesy of Montross Weatherproofing Systems Inc.)

David Montross prides himself on his company’s ability to do it all. Montross, the President of Montross Weatherproofing Systems Inc. in Lake Forest, Calif., is a fourth-generation roofer. He has an original proposal from his great grandfather dated Dec. 13, 1900, for a new roof, chimney and flashing - all for $65.

Of course, prices have risen since then, but Montross Weatherproofing still demonstrates an old-school commitment to quality work in both the commercial and residential markets.

“We’re unique,” Montross said. “We’re not just a roofing contractor. We’re a waterproofer, a deck coating contractor - we cover the entire building envelope, including below grade. We’re versatile. We do the little specialty things others can’t do. We can do additional projects for our customers, like waterproofing decks, pools, and fountains. We get our hands dirty and get things done.”

When it came time to install the roof, Montross was ready. The roof design included multiple levels that rise from 10 feet to 50 feet to match the surrounding topography. The homeowners wanted a slate roof with a section of solar panels, but after consulting with Montross they decided to install a slate roof in conjunction with a built-up, three-ply modified roof system from GAF Materials Corporation to accommodate the solar panels.

“For the solar roof section we were able to help re-engineer and put down a built-up modified roof,” said Montross. “We helped lay out the plan for the solar panels. We were able to influence the owner and architect to go to a more serviceable roof for that section.”

All of the materials were chosen to withstand the extreme conditions of the Pacific Coast. The slate was specifically chosen to withstand he the harsh environment. Fasteners were either stainless steel or copper, depending on the application, and copper was used for all the exposed metal, including the flashing, corbel wraps, gutters, spikes and ferrules. The metal was all done in house and fabricated on site. The company also waterproofed three main decks and various balcony decks.

The overriding philosophy for this job, according to Montross, was the same as any other: “Do it right the first time. You don’t want to go back.”

The 7,000-square-foot-roof includes approximately 6,500 square feet of slate. The remaining surface is comprised of a built-up, three-ply modified roof system designed to accommodate solar panels.

The fall start was problematic, and the schedule barely allowed enough room to complete the project before winter set in. Weather, scheduling the various crews, and coping with members of other trades were all key challenges on the project, but safety was always the greatest concern.

“The biggest challenge was fall protection,” said Montross. “We maintained safety lines on 10 or 12 different levels. Having retractable harnesses and lines was key. On one side you’d be down five feet to the deck; on the other side you’d be down 50 feet into the dirt.”

Approximately 95 percent of the 7,000 square feet of roof space was covered in slate. For the slate, the homeowners wanted a six-color blend, with equal amounts of each color randomly laid. “We were able to work with the owner to match their needs. It took a little more time, but we worked with the manufacturer. American Slate helped us out and packaged it that way. The customer is always right, right?”

Given the start date, they all knew weather could be a concern. “Sometimes the fog rolled in so thick you couldn’t even see,” he said. “It took us right off the project. And there were some rain days as well. So, you could say we had weather issues.”

Coordinating the work at each stage was crucial to meeting the schedule, and the company made sure the members of the built-up crew, shingle crew and sheet metal crew were all on the same page. “The key was getting the right crew out there at the right time,” Montross said. “We made sure we had the right guys doing the right scope. We aren’t trying to force a square peg into a round hole. Our crews are diversified, and there’s some overlap, but we always make sure our crews are doing the work they’re the most comfortable doing.”

Montross employees David Montross, Brigitte Markwell, Vinnie Palladino, Jeff Craig and Larry Balicki gather outside the company’s headquarters.

The three members of the sheet metal crew did all the metal fabrication and installed all of the custom gutters. “These guys are true craftsmen. They have the eye. They can just look at the spot and make sure they can fit it perfectly.”

The tight schedule led to some problems caused by members of other trades. Crews sometimes found that window installers, painters doing touch-up work, and inspectors damaged tiles, but the slate crew promptly handled any replacements.

“The schedule given to us was very tight,” said Montross, looking back at the project. “The best-laid plans would’ve had a spring or early summer start. But we worked with the parameters given by the customers. The schedule was tough. In the end, it all worked out.”

“It was a nice little job,” he concluded. “It was unique. It had some scopes that were custom, so we were able to use the strengths of all of our different crews. There were challenges - weather, the time of year, problems with other trades - but all in all it went very well. The customer had the resources to design a better system, and we were able to work with him and make suggestions to make sure he got what he wanted.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!