Design Intervention

Tapered insulation can do more than eliminate ponding water and ensure proper drainage of low-slope roofs. With the correct design, tapered insulation can help protect roofing components, increase the value of a building and decrease its energy costs. In the words of Dale Redger, national manager of the Allied Tapered Design Center, “It is simple - a properly installed tapered system will provide a longer-lasting roofing system.

Tapered insulation can do more than eliminate ponding water and ensure proper drainage of low-slope roofs. With the correct design, tapered insulation can help protect roofing components, increase the value of a building and decrease its energy costs. In the words of Dale Redger, national manager of the Allied Tapered Design Center, “It is simple - a properly installed tapered system will provide a longer-lasting roofing system.”

The key to proper drainage design is to create sufficient positive slope in all areas of the roof, says Redger. “Ponding water can rapidly deteriorate some roofing membranes, causing premature failure,” he notes. “Tapered insulation also reduces the risk of mold and mildew and will remove the stress of additional weight from the structure.”

For over 20 years, Allied Building Products Corp. has been providing tapered design services to its customers in the form of its Tapered Design Center (TDC). The TDC has centers in Phoenix, West Allis, Wis., and East Rutherford, N.J. An overwhelming majority of its customers - some 95 percent - are roofing contractors, and last year the TDC’s 11 employees accounted for more than 5,400 projects quoted.

According to Redger, the TDC provides timely and accurate pricing and application information to contractors so they can confidently price any tapered insulation requirements their project may have. Once a project is awarded, the TDC provides shop drawings, which map out the installation procedure, along with material breakdowns for each roof area to minimize the movement of material on the roof. Redger maintains that TDC shop drawings are concise and easy to follow. “Each row is labeled to a corresponding cross-section showing the material required. The total thickness of the row is also shown on the cross-section.”

The TDC can work with information in a variety of formats. “Faxes are very common and effective,” says Redger. “They provide a fast method to get information to the design centers. One problem with faxes is they can easily become distorted. Hard copies of plans seem to be becoming less prevalent in our industry, but they still present one of the best methods to examine the requirement of a project, although they are bulky and expensive to ship. The electronic image is the preferred method to receive information. Having the ability to view a full set of plans and specifications online give us the most efficient set of circumstances. We also obtain quite an assortment of requests via e-mail. This method works quite well, provided all the information required is included. The sender must make certain they have included all the relevant information.”

Redger cautions that many architectural plans do not indicate whether the structure is sloped or if tapered insulation is required. “It is very common to have conflicting information between sheets of plans or between plans and specifications,” he notes. Remedial applications can pose additional problems. “Generally speaking, a reroofing project that requires the use of tapered insulation will require a site visit by someone to determine what slope currently exists. It is not uncommon to find low areas caused by settling that would require extra attention.”

Once the information is received, the design centers utilize a wide variety of software programs to create their quotations and drawings. “Taper-Plus is an excellent tool to design and estimate tapered systems and is used by all of our designers,” says Redger. “We use the latest version of AutoCAD to complete shop drawing and view plans submitted by several of our customers. We are equipped with the latest computer technology along with large-scale copiers, plotters and scanners. Our large format copier allows us to copy plans and return them to our customers without delay. With our scanning capabilities, we can import plan images directly into our software for complete accuracy. We are also equipped with a large-scale laminator, and we laminate the field copy of our shop drawing for greater durability.”

The Allied Building Products branches have the ability and equipment to deliver and roof load a tapered system, states Redger. “The most common tapered panels are manufactured from isocyanurate and are available in 4-foot by 4-foot panels with slopes from 1/16 of an inch to 1/2 inch per foot.” He notes that other slopes are available when using other materials, such as expanded and extruded polystyrene. Perlite and wood fiber also offer a great variety of slopes.

“It is also important to count all the material you receive and to properly stage the material on the roof,” he advises. “Planning your job in advance will make things run much more smoothly. Having your roofers searching for the next panels can significantly slow your productivity. The TDC can provide loading charts when the project has multiple decks.”

Redger notes that while Allied’s sales team is quick to point out the virtues of the TDC to roofing professionals, most roofing contractors learn about the service from their peers. “Our greatest marketing has been word of mouth from our customers and colleagues."

Sorenson appreciates the quick turnaround he has come to expect when he’s at the quote stage. “During the bidding process, they are able to give me the information I need for an accurate quote,” he says, and this allows him to quickly determine how much material he’ll need for the installation. “Then they provide us with the submittal drawings, as well as a laminated copy for the guys in the field to follow.”

According to Sorenson, the key to the process is simple: “Make sure the Tapered Design Center has all the information you can give them.” But he notes that if something’s missing, the reps from the TDC are sure to follow up with questions. “They’re really responsive,” states Sorenson. “If I’m behind the eight-ball when it comes to bids, they’ll turn it around quickly for me. They’re good, their drawings are accurate, and I like working with them.”

Steve Shand, president of R.S. Roofing and Sheet Metal, Nanuet, N.Y., also appreciates the quick turnaround time when it comes to quotations in the time-sensitive world of commercial construction. “If a school bid is due on Tuesday, getting a price on Wednesday doesn’t do me any good,” he says.

R.S. Roofing has been in business for 45 years, and the company does 100 percent commercial work, the lion’s share of it in new construction. Right now, the majority of the company’s jobs involve hospital projects, but a decade ago schools were the most popular segment of the market. Shand jokes that the company has been using the services of the TDC “since there was tapered insulation.”

Providing information to the Tapered Design Center is relatively easy, he notes, as the company does a lot of plan and spec work, and detailed drawings are easily accessible and contain most of the information needed to complete the design phase. “We’ll pick up the drawings or get them online,” he says. “In some cases, I’ve dropped off some drawings or a disk when I’ve driven by the East Rutherford center, and by the time I got back to the office, I had the prices for the quote sitting at the fax machine.”

When it comes to roof replacement projects, speed is of the essence, asserts Shand. “In this business, when someone decides to get a new roof, they want a price right away,” he notes. “They’ve put it off for a year or two too long in most cases. Then, when you come out and measure in the morning, they want a price that afternoon.”

With existing buildings, sometimes a simple sketch or scale drawing will suffice, as long as the drains are marked and low spots are indicated. “Sometimes in older buildings the roof can settle, while the drains, which are on columns, stay high,” Shand points out. The TDC can let him know when tapered insulation can create the proper slope or if the drains should be relocated.

One particularly complex job involved the new science building at Mount St. Mary College in Newburgh, N.Y., which needed nine layers of tapered insulation to get the proper slope. “When you’re installing that much material, you have to make sure the drawings are both detailed and easy to follow,” he says. The result? “Water doesn’t pond anywhere, and there are over 60 penetrations.”

Shand offers a word of caution regarding drawings of existing buildings. “Make sure from the beginning that the drawings match the building,” he says, noting that sometimes architects might pull old drawings out of the archives that don’t reflect new rooftop equipment or other additions. “You’ve got to do your homework beforehand and make sure the drawings reflect the roof as it is now.”

The use of tapered insulation is second nature to architects and specifiers, but Shand notes that building owners are better informed than ever, thanks in part to the Internet. “Construction buyers are a lot more sophisticated than they were 15 years ago, and there is a great benefit to a more educated buyer,” he says. “My dad always used to say, ‘A little knowledge is a dangerous thing,’ and we’ve all run into someone who thinks he’s an expert because he watched two seasons of ‘This Old House,’ but in general, education is a good thing. People realize that there’s a lot of new technology out there, a lot of ways to make the roof better.”

Tapping into the expertise of the Tapered Design Center can be crucial, notes Glasgow. “Occasionally, architects can draw it up wrong, and they’ll spot the problem,” he says. “They’ll take a look and tell us what is going to work on that roof and what is not.” He typically provides a copy of the drawings, a copy of the details, the structural drawings and the specifications for each project.

“New roofs are more cut and dried, but reroofing projects are sometimes tricky,” states Glasgow. “If there’s a problem with an existing roof, they’ll help us with it.”

He notes that in a recent project involving a school building roof in Pacific Palisades, Dale Redger flew out to the site, went up on the roof and inspected the problem areas and made sure low spots would be accurately reflected in the drawings. “He worked it out so that we got all of the water off of that roof,” says Glasgow. “We were able to cope with some very difficult existing conditions.”

He explains that the drawings are easy to follow. “They know that roofers are installing the system in the field, and they know that roofers have to understand the drawings in the field.” Glasgow typically receives five or six sets of submittal drawings with an order, and he especially appreciates the laminated copy for use at the jobsite, so workers can make notations as the installation progresses.

Glasgow adds that the representatives of Allied’s Tapered Design Center can provide a wealth of information for contractors unfamiliar with the benefits of tapered insulation. “If you don’t know tapered insulation, they’ll explain it to you, they’ll show you how to install it, and they’ll show you what you’re doing wrong” he says.

“They don’t just give you the drawings and send you on your way. They’ll go with you to pre-construction meetings and explain the design to the architect if the architect has any questions.” It’s that level of dedication that sets the Allied Tapered Design Center apart, says Glasgow. “You get that extra personal touch with Allied’s service.”

For more information about Allied Building Products’ Tapered Design Center, visit www.tdcroof.com or call 888-832-7663.

Tapered insulation can do more than eliminate ponding water and ensure proper drainage of low-slope roofs. With the correct design, tapered insulation can help protect roofing components, increase the value of a building and decrease its energy costs. In the words of Dale Redger, national manager of the Allied Tapered Design Center, “It is simple - a properly installed tapered system will provide a longer-lasting roofing system.”

The key to proper drainage design is to create sufficient positive slope in all areas of the roof, says Redger. “Ponding water can rapidly deteriorate some roofing membranes, causing premature failure,” he notes. “Tapered insulation also reduces the risk of mold and mildew and will remove the stress of additional weight from the structure.”

For over 20 years, Allied Building Products Corp. has been providing tapered design services to its customers in the form of its Tapered Design Center (TDC). The TDC has centers in Phoenix, West Allis, Wis., and East Rutherford, N.J. An overwhelming majority of its customers - some 95 percent - are roofing contractors, and last year the TDC’s 11 employees accounted for more than 5,400 projects quoted.

According to Redger, the TDC provides timely and accurate pricing and application information to contractors so they can confidently price any tapered insulation requirements their project may have. Once a project is awarded, the TDC provides shop drawings, which map out the installation procedure, along with material breakdowns for each roof area to minimize the movement of material on the roof. Redger maintains that TDC shop drawings are concise and easy to follow. “Each row is labeled to a corresponding cross-section showing the material required. The total thickness of the row is also shown on the cross-section.”

Dale Redger is national manager of the Allied Tapered Design Center, with locations in East Rutherford, N.J., West Allis, Wis., and Phoenix.

Crucial Information

In order to complete the design, the TDC needs to receive key information about the project. “We need to be able to draw the area to scale, so building dimensions must be provided, along with drain locations and location and size of any obstruction that will affect the design,” says Redger. “The type of material to be used, the slope required, minimum starting thickness of the system or a required R-value are also needed. The TDC Web site, www.tdcroof.com, contains a quote request form that conveniently lists the required information.”The TDC can work with information in a variety of formats. “Faxes are very common and effective,” says Redger. “They provide a fast method to get information to the design centers. One problem with faxes is they can easily become distorted. Hard copies of plans seem to be becoming less prevalent in our industry, but they still present one of the best methods to examine the requirement of a project, although they are bulky and expensive to ship. The electronic image is the preferred method to receive information. Having the ability to view a full set of plans and specifications online give us the most efficient set of circumstances. We also obtain quite an assortment of requests via e-mail. This method works quite well, provided all the information required is included. The sender must make certain they have included all the relevant information.”

Redger cautions that many architectural plans do not indicate whether the structure is sloped or if tapered insulation is required. “It is very common to have conflicting information between sheets of plans or between plans and specifications,” he notes. Remedial applications can pose additional problems. “Generally speaking, a reroofing project that requires the use of tapered insulation will require a site visit by someone to determine what slope currently exists. It is not uncommon to find low areas caused by settling that would require extra attention.”

Once the information is received, the design centers utilize a wide variety of software programs to create their quotations and drawings. “Taper-Plus is an excellent tool to design and estimate tapered systems and is used by all of our designers,” says Redger. “We use the latest version of AutoCAD to complete shop drawing and view plans submitted by several of our customers. We are equipped with the latest computer technology along with large-scale copiers, plotters and scanners. Our large format copier allows us to copy plans and return them to our customers without delay. With our scanning capabilities, we can import plan images directly into our software for complete accuracy. We are also equipped with a large-scale laminator, and we laminate the field copy of our shop drawing for greater durability.”

The Allied Building Products branches have the ability and equipment to deliver and roof load a tapered system, states Redger. “The most common tapered panels are manufactured from isocyanurate and are available in 4-foot by 4-foot panels with slopes from 1/16 of an inch to 1/2 inch per foot.” He notes that other slopes are available when using other materials, such as expanded and extruded polystyrene. Perlite and wood fiber also offer a great variety of slopes.

“It is also important to count all the material you receive and to properly stage the material on the roof,” he advises. “Planning your job in advance will make things run much more smoothly. Having your roofers searching for the next panels can significantly slow your productivity. The TDC can provide loading charts when the project has multiple decks.”

Redger notes that while Allied’s sales team is quick to point out the virtues of the TDC to roofing professionals, most roofing contractors learn about the service from their peers. “Our greatest marketing has been word of mouth from our customers and colleagues."

Contractor Success Stories

Al Sorenson, president of Century Roofing Corp., Calumet Park, Ill., has used the services of the Allied Tapered Design Center for more than a decade. Century Roofing has been in business over 25 years, and the company does 100 percent of its business in the commercial arena, 95 percent of it in new construction, including large home centers such as Lowe’s and Wal-Mart stores. Using the Allied Tapered Design Center has become standard procedure for almost every job, says Sorenson. “Ninety-five percent of the work we do has tapered insulation in it, with saddles, crickets, etc.” he explains. “We provide the drawings and e-mail them any additional information, such as the type of roof system, the specs, and the minimum R-values and minimum thicknesses for insulation.”Sorenson appreciates the quick turnaround he has come to expect when he’s at the quote stage. “During the bidding process, they are able to give me the information I need for an accurate quote,” he says, and this allows him to quickly determine how much material he’ll need for the installation. “Then they provide us with the submittal drawings, as well as a laminated copy for the guys in the field to follow.”

According to Sorenson, the key to the process is simple: “Make sure the Tapered Design Center has all the information you can give them.” But he notes that if something’s missing, the reps from the TDC are sure to follow up with questions. “They’re really responsive,” states Sorenson. “If I’m behind the eight-ball when it comes to bids, they’ll turn it around quickly for me. They’re good, their drawings are accurate, and I like working with them.”

Steve Shand, president of R.S. Roofing and Sheet Metal, Nanuet, N.Y., also appreciates the quick turnaround time when it comes to quotations in the time-sensitive world of commercial construction. “If a school bid is due on Tuesday, getting a price on Wednesday doesn’t do me any good,” he says.

R.S. Roofing has been in business for 45 years, and the company does 100 percent commercial work, the lion’s share of it in new construction. Right now, the majority of the company’s jobs involve hospital projects, but a decade ago schools were the most popular segment of the market. Shand jokes that the company has been using the services of the TDC “since there was tapered insulation.”

Providing information to the Tapered Design Center is relatively easy, he notes, as the company does a lot of plan and spec work, and detailed drawings are easily accessible and contain most of the information needed to complete the design phase. “We’ll pick up the drawings or get them online,” he says. “In some cases, I’ve dropped off some drawings or a disk when I’ve driven by the East Rutherford center, and by the time I got back to the office, I had the prices for the quote sitting at the fax machine.”

When it comes to roof replacement projects, speed is of the essence, asserts Shand. “In this business, when someone decides to get a new roof, they want a price right away,” he notes. “They’ve put it off for a year or two too long in most cases. Then, when you come out and measure in the morning, they want a price that afternoon.”

With existing buildings, sometimes a simple sketch or scale drawing will suffice, as long as the drains are marked and low spots are indicated. “Sometimes in older buildings the roof can settle, while the drains, which are on columns, stay high,” Shand points out. The TDC can let him know when tapered insulation can create the proper slope or if the drains should be relocated.

One particularly complex job involved the new science building at Mount St. Mary College in Newburgh, N.Y., which needed nine layers of tapered insulation to get the proper slope. “When you’re installing that much material, you have to make sure the drawings are both detailed and easy to follow,” he says. The result? “Water doesn’t pond anywhere, and there are over 60 penetrations.”

Shand offers a word of caution regarding drawings of existing buildings. “Make sure from the beginning that the drawings match the building,” he says, noting that sometimes architects might pull old drawings out of the archives that don’t reflect new rooftop equipment or other additions. “You’ve got to do your homework beforehand and make sure the drawings reflect the roof as it is now.”

The use of tapered insulation is second nature to architects and specifiers, but Shand notes that building owners are better informed than ever, thanks in part to the Internet. “Construction buyers are a lot more sophisticated than they were 15 years ago, and there is a great benefit to a more educated buyer,” he says. “My dad always used to say, ‘A little knowledge is a dangerous thing,’ and we’ve all run into someone who thinks he’s an expert because he watched two seasons of ‘This Old House,’ but in general, education is a good thing. People realize that there’s a lot of new technology out there, a lot of ways to make the roof better.”

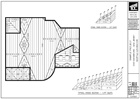

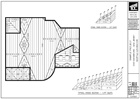

This drawing of the plan for a hospital in Colorado Springs, Colo., shows how complicated a tapered insulation project can be. This job involved several intersecting circular decks and interior drains that had been modified by a plumbing contractor due to conditions inside the building.

Help for Those in the Field

Letner Roofing, Orange, Calif., has been making roofs better for 50 years. The company has 300 employees, and it does 60 percent new construction and 40 percent reroofing. Letner Roofing has benefited from the services of the Allied Tapered Design Center for a decade or so. Ernie Glasgow, vice president of Letner Roofing, says the reasons are simple: “They give us accurate quotes, and if I send it there, I know the drawings will be accurate as well.”Tapping into the expertise of the Tapered Design Center can be crucial, notes Glasgow. “Occasionally, architects can draw it up wrong, and they’ll spot the problem,” he says. “They’ll take a look and tell us what is going to work on that roof and what is not.” He typically provides a copy of the drawings, a copy of the details, the structural drawings and the specifications for each project.

“New roofs are more cut and dried, but reroofing projects are sometimes tricky,” states Glasgow. “If there’s a problem with an existing roof, they’ll help us with it.”

He notes that in a recent project involving a school building roof in Pacific Palisades, Dale Redger flew out to the site, went up on the roof and inspected the problem areas and made sure low spots would be accurately reflected in the drawings. “He worked it out so that we got all of the water off of that roof,” says Glasgow. “We were able to cope with some very difficult existing conditions.”

He explains that the drawings are easy to follow. “They know that roofers are installing the system in the field, and they know that roofers have to understand the drawings in the field.” Glasgow typically receives five or six sets of submittal drawings with an order, and he especially appreciates the laminated copy for use at the jobsite, so workers can make notations as the installation progresses.

Glasgow adds that the representatives of Allied’s Tapered Design Center can provide a wealth of information for contractors unfamiliar with the benefits of tapered insulation. “If you don’t know tapered insulation, they’ll explain it to you, they’ll show you how to install it, and they’ll show you what you’re doing wrong” he says.

“They don’t just give you the drawings and send you on your way. They’ll go with you to pre-construction meetings and explain the design to the architect if the architect has any questions.” It’s that level of dedication that sets the Allied Tapered Design Center apart, says Glasgow. “You get that extra personal touch with Allied’s service.”

For more information about Allied Building Products’ Tapered Design Center, visit www.tdcroof.com or call 888-832-7663.

Links

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!