Solar Mounting News

‘Hidden-Fastener’ Solar Mount Surpasses Rigorous Mechanical Test Standards

Mounting innovation offers exceptional uplift resistance

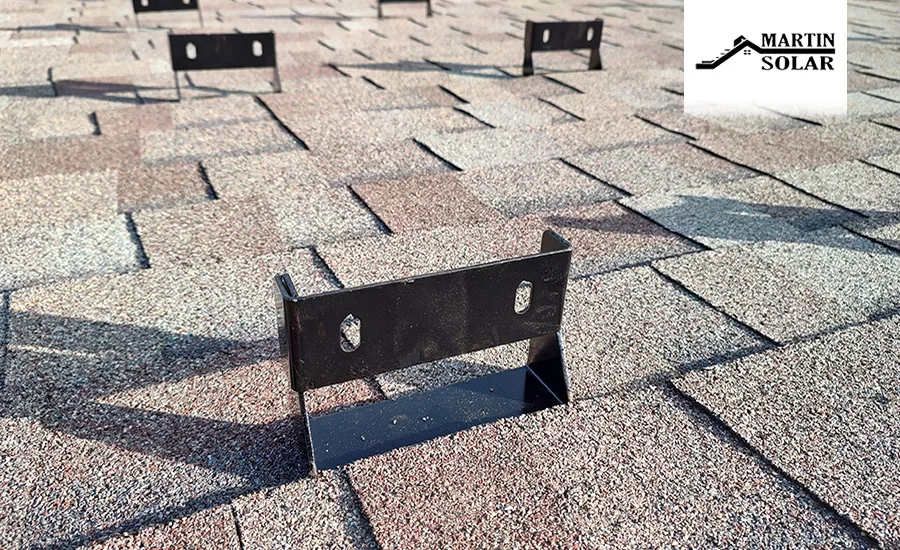

The Hidden-Fastener Solar Mount by Martin Solar underwent uplift testing at CSA Group, demonstrating structural endurance six times above the UL 2703 standard.

— Image courtesy of Martin Solar

Martin Solar, a solar manufacturer based in Mascoutah, Ill., announced earlier this week that its Hidden-Fastener Solar Mount, a solar attachment system, exceeded industry-standard mechanical testing benchmarks conducted by CSA Group, validating its structural durability under extreme conditions.

The HFSM was tested in uplift scenarios using Unirac rails and panel clamps, achieving a load resistance up to six times greater than the baseline UL 2703 requirement, which already includes a 1.5 times safety factor, the company said in a news release.

“Uplift resistance has always been HFSM's weakest attribute,” said Preston Nelson, director of Martin Solar and co-inventor of HFSM.

“To see it withstand loads six times higher than the standard gives us real confidence in the long-term integrity of this mounting system,” he added. “This data places HFSM among the most resilient solar mounts on the market, particularly in direct-to-deck installations, though it is also truss-compatible.”

Deformation-Based Failure Mode

During testing, the HFSM system exhibited gradual deformation, starting at a total load of 2,673 pounds. Final failure occurred at 3,500 pounds, when a panel clamp detached from the rail. Nelson emphasized the mount’s unique failure mechanics as an added benefit.

“We invented HFSM to be leak-proof, but it turns out its design benefits extend even to failure behavior,” Nelson said.

“Unlike rigid systems that tend to snap during extreme uplift events — such as tornadoes — the HFSM distributes forces over space and time, like an airbag or bungee cord,” he explained. “That’s a game-changer for Midwest contractors who routinely deal with severe weather.”

Leak-Proof Design for Asphalt and Synthetic Slate

HFSM is engineered specifically for asphalt shingles and synthetic slate roofs. Designed in collaboration with roofing and solar professionals at Martin Solar and Martin Roofing, the system features a leak-proof attachment method that secures below the shingles at the traditional nail strip — eliminating the need for surface-penetrating fasteners.

DOE Recognition and Commercialization Push

Martin Solar recently earned a $50,000 award from the U.S. Department of Energy as part of American-Made Solar Prize Round 8, recognizing the HFSM system’s innovation and potential.

The company is currently a semifinalist in a nationwide competition that supports emerging solar technologies through funding and access to the American-Made Network, comprising national labs, investors, and incubators.

Finalists for the program are expected to be announced this summer by the National Renewable Energy Laboratory (NREL).

Selected teams will receive $100,000 in prize money, a $90,000 laboratory voucher, and a presentation slot at RE+, the world’s largest renewable energy expo, held Sept. 8–11 in Las Vegas.

For more information, visit martinmount.net.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!