Research and Technology News

Researchers Offer ‘Adaptive Roof Tile’ Concept That Responds to Outside Temp., Reduces Energy Consumption

Scientists at the University of California Santa Barbara published academic paper on roof tiles that can cut heat and cooling costs without the use of electricity

Researchers at the University of California, Santa Barbara, published a study on the concept of “adaptive roof tiles” that can reduce heating and cooling costs. In short, the tiles can switch between a heating and cooling state depending on the tile's temperature; the target temperature is around 65° F.

— Photo courtesy of University of California Santa Barbara

A research paper published on Tuesday in the academic journal Device offers an alluring prospect to the roofing industry: an adaptive roof tile, which, when deployed in arrays on roofs, can lower heating bills in winter and cooling bills in summer without the need for electronics.

The paper’s authors, UC Santa Barbara researchers Charlie Xiao, Elliot Hawkes, and Bolin Liao, have been working on the project with the aim of reducing costs on Americans’ energy bills as well as reducing the consumption of fossil fuels to run in-home HVAC systems.

The article, titled “Passively adaptive radiative switch for thermoregulation in buildings,” is objectively a mouthful, but the paper’s highlights cut to the chase:

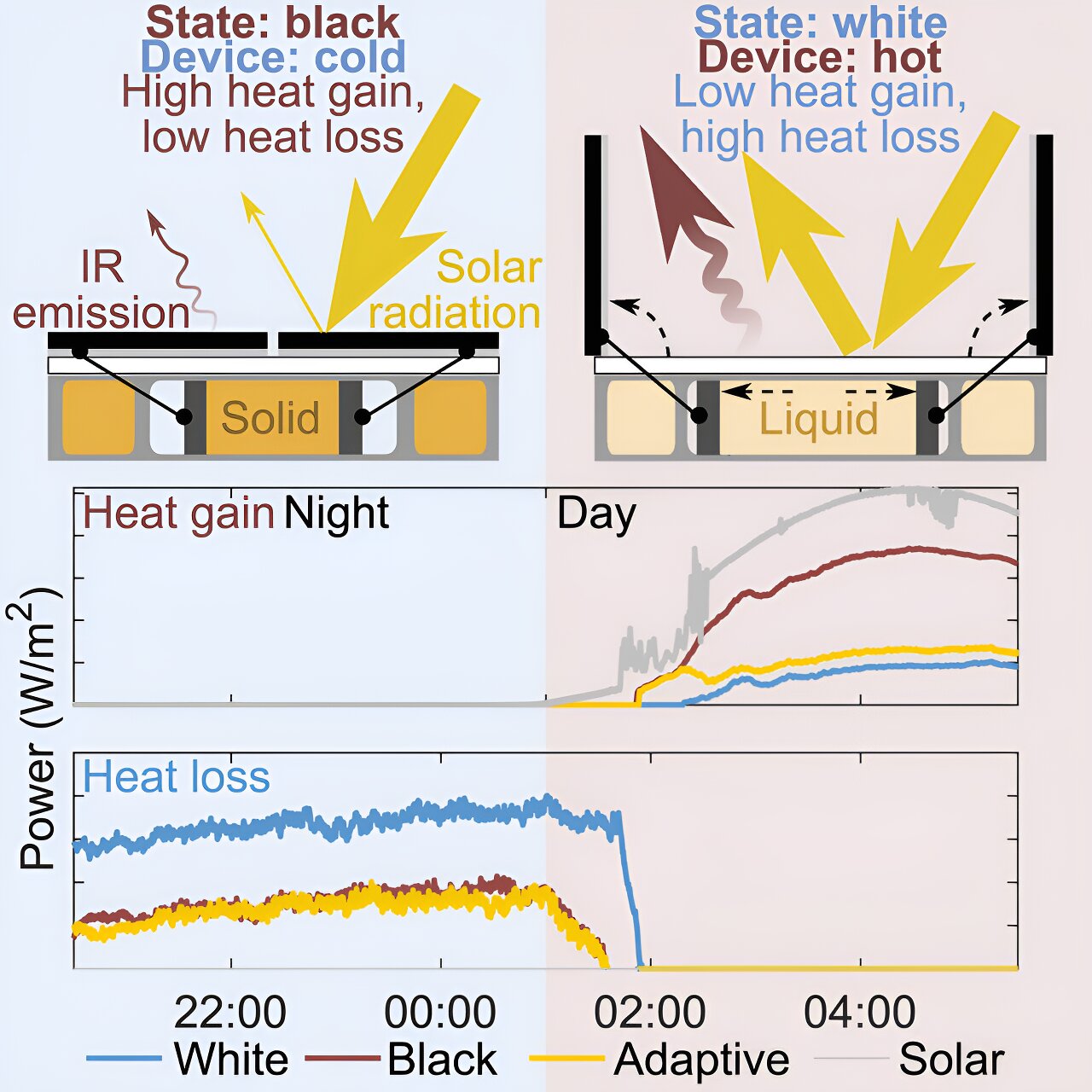

- Tile-like radiative switch passively switches between cooling and heating states

- Switches between cooling and heating states within 3 degrees Celsius (34 degrees Fahrenheit) of the switch temperature

- Compared with static devices, it reduces cooling and heating needs by more than 2.5 times

"It switches between a heating state and a cooling state, depending on the temperature of the tile," Xiao, the lead author of the study, told the website TechXplore in a Dec. 13 interview. "The target temperature is about 65 degrees Fahrenheit — about 18 degrees Celsius."

The passive thermoregulation device, which is about 4 inches square, is a blend of Liao's expertise in thermal science and Hawkes's work in mechanism design — a movable surface that, as TechXplore describes, can change its thermal properties in response to a range of temperatures. The idea for the project, they said, came to them during long drives between Santa Barbara and northern California a few years ago.

"Both our spouses were in Stanford at the time, so we were taking trips and wondering what we could potentially do together," said Liao, who, like Hawkes, is a professor in UCSB's Department of Mechanical Engineering. They then began to design mechanically tunable thermal devices.

It’s A Technical Thing

Xiao said he landed on the idea of using a wax motor, which allowed the concept of adaptive roof tiles to take its final shape. Based on the change in the volume of wax due to temperatures to which the wax is exposed, a wax motor creates pressure that moves mechanical parts, translating thermal energy into mechanical energy. Wax motors are not a new concept: you can find them in various appliances, including dishwashers and washing machines, as well as in more specialized applications, including those used in the aerospace industry.

For roof tiles, the wax motor — depending on its state — can push or retract pistons that close or open louvers on the tile's surface. Therefore, in cooler temperatures, while the wax is solid, the louvers are closed and lay flat, exposing a surface that absorbs sunlight and minimizes heat dissipation through radiation.

But, as the paper makes clear, as soon as the temperatures reach around 64.5 degrees Fahrenheit, the wax begins to melt and expand, pushing the louvers open and exposing a surface that reflects sunlight and emits trapped heat.

In addition, the paper states that during the melting or freezing process, the wax also absorbs or releases a large amount of heat, ambient temperature-dependent, further stabilizing the temperature of the tile and the building.

"So we have a very predictable switching behavior that works within a very tight band," Xiao explained.

According to the paper’s conclusions, testing has demonstrated a reduction in energy consumption for cooling by 3.1 times and heating by 2.6 times compared with non-switching devices covered with conventional reflective or absorbing coatings.

Because of the wax motor, no electronics, batteries or external power sources are required to operate the device. Unlike other similar technologies, it is responsive within a few degrees of its target range.

Additionally, its design lends itself to customization, meaning different thermal coatings and various types of wax can be used to allow the device to operate at desired temperature ranges while also lending itself toward mass manufacture.

"The device is still a proof-of-concept, but we hope it will lead to new technologies that one day could have a positive impact on energy expenditure in buildings," said Hawkes.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

.webp?height=200&t=1732671214&width=200)