Owens Corning Introduces New Asphalt Shingle Recycling Initiatives to Create a Circular Economy

Owens Corning is addressing asphalt shingle waste head on with new recycling initiatives that aim to keep tons of shingles out of landfills and create a circular economy.

The Environmental Protection Agency reports nearly 11 to 13 million tons of asphalt shingles end up in landfills on an annual basis. Through its enhanced recycling program, Owens Corning intends to recycle 2 million tons of shingles per year by 2030.

“We’ve been testing various approaches to this for more than 20 years,” Gunner Smith, Owens Corning Roofing president, told RC. “We believe the approach we’re taking today – we’ve been working on for the last several years – has great potential. Our partners on this are experts on processing and recycling and we’re working together to bring this from a lab scale, which was proven there, to a pilot line we’re announcing as a way to move towards commercialization.”

The company has launched workstreams focused on two methods of shingle recycling: recycling shingles into new shingles and recycling shingles into asphalt pavement. Both approaches intend to reclaim 100% of the shingle to eliminate product waste.

Recycled Shingles to New Shingles

By partnering with ASR Systems and CRS Reprocessing Services, the pilot asphalt recycling program will be constructed and run by CRS on the grounds of Indiana Shingle Recycling in Indianapolis. The program utilizes several proprietary, patented processes to deconstruct post-consumer and post-industrial shingles to extract individual component raw materials.

The process begins by mechanically removing granules before the shingles are pulverized into a powder. That powder is put through an extraction process that further breaks it down into basic components. This produces clean streams of liquid asphalt, clean granules and limestone filler. These are shipped to Owens Corning facilities and incorporated back into the shingle production process.

Smith said those materials individually are more valued than other forms of recycled shingles, and as a result, the company can use them in more places.

“We have invested in shingle recycling efforts through both internal expertise and collaboration with external partners. This has generated significant learnings that will enable us to accelerate our shingle recycling ambitions and advance this work across the industry to keep shingles out of landfills,” Smith said.

Paving the Way

Owens Corning is using its expertise in asphalt innovation to increase the use of recycled asphalt shingles in the paving market. Previously, the company has diverted 40 million pounds of used shingles from landfills and into pavement since 2020.

Mark Leo, director of circular economy at Owens Corning, said historically, manufacturers have been encouraging contractors to take tear-offs from jobsites and send them to shingle recyclers. Owens Corning’s approach is to work directly with hot-mix asphalt contractors by not only providing them with recycled asphalt product, but provide technical guidance for incorporating their recycled shingles into an asphalt mix that meets federal and state paving requirements.

“If they can be confident that the increased use of recycled asphalt shingles in their mixes is going to give them the same level of performance and same specification, they’re happy to do it,” said Leo. “They can decrease the raw material input cost for the process. Not only that, they can supply their customers with a more sustainable product.”

Doing the Right Thing

Smith said the program is coming at a critical time in the roofing industry, as he believes it will face regulations in the future and have limited space in landfills dedicated to end-of-life shingles.

“This can solve that limitation for the industry while doing the right thing as an industry for the environment,” he said.

Owens Corning plans on doing hands-on training with roofing contractors to better educate them on the process, which will in turn allow them to explain to customers the product options they have to contribute to a sustainable future while protecting their homes.

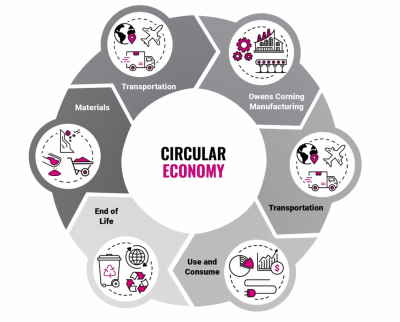

Leo said advancing a circular economy — ensuring materials remain in the economy indefinitely instead of a landfill — is the next chapter for the industry.

“We have a 2030 Sustainability Goal of zero waste to landfill, so that means across all our plants globally, we aspire to be zero waste to landfill across that entire network,” he said. “We’re trying to lead the roofing industry from the traditional linear economy into the circular economy space.”

Sustainability in its DNA

In its 16th annual sustainability report published earlier this year, Owens Corning noted its progress toward its 2030 Sustainability Goals. These goals are built on three pillars: expanding the company’s product handprint, reducing its environmental footprint, and increasing its social handprint.

“Owens Corning has a strong sustainability foundation and has set ambitious goals,” said David Rabuano, senior vice president and chief sustainability officer, in a written statement. “We are focused on bringing these breakthrough solutions to life as a critical next chapter of work in our sustainability journey. Our mission is to build a sustainable future through material innovation, and with this enhanced focus on shingle recycling we continue to make progress.”

The company has amassed a number of recognitions for its sustainability work. This includes being the first company to earn the top spot on the 100 Best Corporate Citizens List from 3BL Media for four consecutive years. In 2021, Dow Jones Sustainability World Index included Owens Corning for the 12th consecutive year while Chair and Chief Executive Officer Brian Chambers was named Responsible CEO of the Year for ESG Transparency by 3BL Media.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!