Project Profile: Liberty’s Patriotic Solar Array

.webp?t=1646406752)

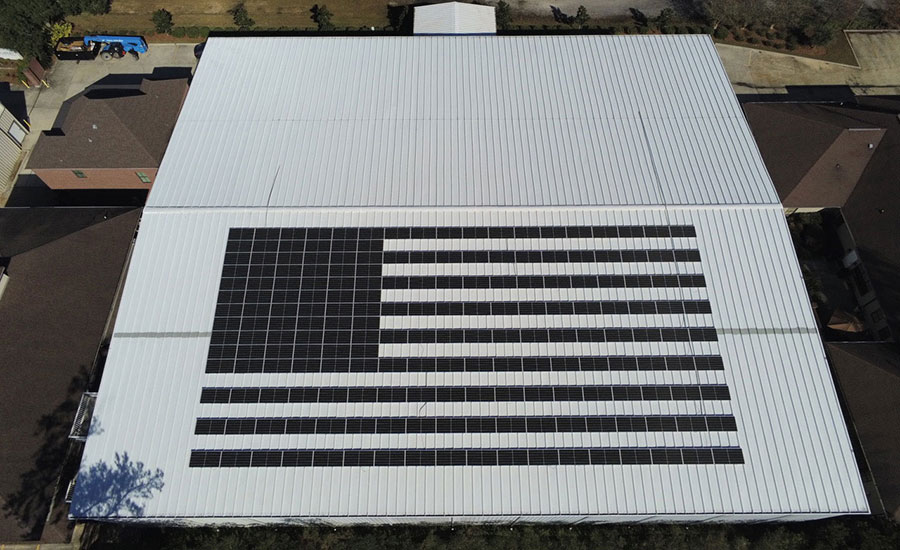

To honor its name and ideals, Liberty Self Storage asked contractors to take a novel approach during a solar roof conversion project.

The company is a multi-site storage facility business in Louisiana and the state's largest solar-powered company. Liberty Self Storage dedicated itself to green energy in 2016, commissioning solar conversion for the first nine of 12 locations in St. Tammany Parish.

For this particular project, however, Liberty Self Storage wanted to do something different. They contacted The Next Energy Technology, a Louisiana-based solar power company, to design and install a U.S. flag solar panel array at its facility located in Covington, La., as a symbolic source of pride and unity for all Americans.

In trading string inverters for 64 APsystems microinverters, the project became one of the most energy-efficient locations in the Liberty Storage chain.

In trading string inverters for 64 APsystems microinverters, the project became one of the most energy-efficient locations in the Liberty Storage chain.

Solar and Stripes

A traditional rail-mounted system was not ideal for the design because it would add additional weight to the array, and in certain areas, the rails would remain exposed and compromise the design. Additionally, Liberty Storage was adamant that the array be attached to the 72-foot by 166-foot metal roof without any penetrations.

Another challenge was the area’s high wind speeds due to its proximity to the Gulf coast. The design wind load requirements for the roof necessitated a solar mounting product capable of withstanding up to 140-mile-per-hour winds.

Solar solution provider, Ontility, recommended the PVKIT direct-attach™ (rail-less) solar solution paired with the S-5-V Mini clamp to provide a secure, economical and penetration-free method for attaching solar modules to the metal roof. This enabled the solar installers to “lay and play” photovoltaic (PV) modules with tested, engineered, cost-saving attachments. The solution also allowed a precise physical module arrangement to achieve the artistic objective.

The end result is a 74.88 kilowatt DC solar array securely mounted to the MBCI Ultra-Dek standing seam metal roof with the S-5! PVKIT 2.0 solar attachment solution. Trading string inverters for 64 APsystems microinverters in the project design resulted in one of the most energy-efficient locations in the Liberty Storage chain, and helped it take the lead as one of the most progressive mid-sized companies in the South.

S-5!'s solutions allowed a precise physical module arrangement to achieve the artistic objective.

S-5!'s solutions allowed a precise physical module arrangement to achieve the artistic objective.

This Metal Doesn’t Run

In high-wind areas like this project presented, wind forces will try to tear a roof from its mountings. Metal roofing performs exceptionally well in these conditions due in part to its attachment methods and interlocking installation, where panels are interlocked and attached to the structure of the building, thus reducing the ability of wind to disrupt the roof panels.

Standing seam metal has a distinct advantage over other roof types because it serves as a “structural” covering, meaning it can be engineered to withstand almost any force imposed by wind. It also serves as the perfect platform for mounting solar PV because the structural ribs or seams can be used as inherent (and cost-free) “rails” for mounting solar PV via reliable mechanical attachments.

With the standing seam metal roof, good south exposure, no obstructions and a clear objective, The Next Energy Technology was able to overcome any and all challenges. As a result, they transformed a solar array into a symbol of freedom – an American flag.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!