Sunflare Releases PowerFit for Metal Standing Seam Roofs

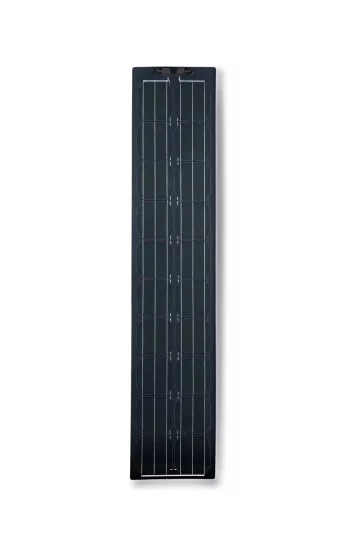

LA VERNE, Calif. — Sunflare’s PowerFit 20 is a light, thin, flexible and nearly invisible solar panel that brings energy without the ugly.

Sunflare’s new PowerFit 20 lies flat, nestling in between the seams of metal standing seam roofs. These modules are for those architects and builders who value the power of aesthetics as well as power of the sun.

Each PowerFit panel is 60 watts and can be seamlessly connected to cover whatever length the roof demands. Installation is fast, easy and low-cost. With PowerFit 20 there are no roof penetrations needed. The modules come with a butyl adhesive backing — just peel and stick for a secure hold that can withstand gale-force winds. Because the modules are light and thin, staging at the installation site takes less than a quarter of the time that staging with traditional panels would take.

Due to the distinct chemistry of Sunflare panels — copper, indium, gallium and selenide — the cells deliver more energy at dawn and dusk than traditional solar panels. As with all Sunflare modules, there is a bypass diode for each individual cell. This means when a cell is shaded, only that individual cell is inactive. Traditional solar panels have a bypass diode per string of cells. Therefore, if just one cell is covered the whole string will not produce power. If the shade is across a single row, the entire panel can be knocked out.

PowerFit 20 modules are produced in an eco-friendly, energy-efficient manufacturing process. Sunflare manufacturing results in 10% of the detrimental global warming gas emissions that silicon panels use from birth through transport to an installation site. The manufacturing process uses very little water, and that which is used is clean and can be reused. The spent materials are recycled. Sunflare panels don’t use glass, don’t need aluminum racking, and are just one quarter of the weight of a silicon panel by themselves.

PowerFit 20 is available for pre-order at sunflare.sunflaresolar.com/powerfit-20.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!