BoltHold™ Anchors

Asphalt Anchors Group

Anchoring to asphalt has come of age. The conventional wisdom holds that the only way to attach anything securely to asphalt is by replacing the asphalt with concrete. Yet the Asphalt Anchors Group (AAG) has developed an economical and reliable way to attach structures directly to asphalt, at a fraction of the cost of concrete replacement. With 10 years of field experience, the technology is ready to go mainstream.

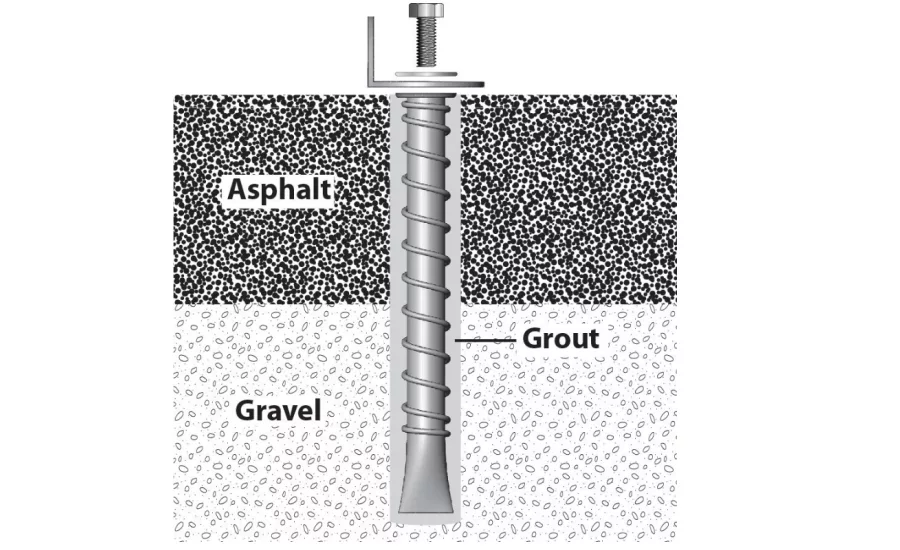

The special-purpose anchors are installed flush with the asphalt surface. An internal thread accepts a bolt that is used to attach the structure to the anchor.

The anchors bond to asphalt using an epoxy or cement (generically called "grout"). An oversize hole is drilled in the asphalt, is filled with a fast curing grout, and the anchor is dropped in until it is flush with the surface. The displaced grout is pushed into the crevices in the asphalt and in the gravel layer below. Thus the grout binds to the anchor on the one side, and the asphalt on the other side. This bond is stronger than the asphalt around it. The anchors and the asphalt are now one, without stress and the passing of time will not loosen the bond.

Uses and Reusability

The applications for the anchors range from the mundane to the exotic. Common applications are mounting parking signs, fence posts, outdoor furniture and speed bumps. Unusual ones anchor jet blast deflectors, runway arresting system (to capture airplanes that overshot the runway) and seasonal flood control systems.

The anchors are popular for seasonal applications where the structure needs to be removed — speed bumps for the winter, tents after a weekend farmer's market. Because they are flush with the surface, then anchor can safely be left installed, for reuse next time.

The anchors are offered in different sizes and materials including all stainless steel anchor for use in areas subject to salt water or close to drinking aware reservoirs.

The special-purpose anchors are installed flush with the asphalt surface. An internal thread accepts a bolt that is used to attach the structure to the anchor.

The anchors bond to asphalt using an epoxy or cement (generically called "grout"). An oversize hole is drilled in the asphalt, is filled with a fast curing grout, and the anchor is dropped in until it is flush with the surface. The displaced grout is pushed into the crevices in the asphalt and in the gravel layer below. Thus the grout binds to the anchor on the one side, and the asphalt on the other side. This bond is stronger than the asphalt around it. The anchors and the asphalt are now one, without stress and the passing of time will not loosen the bond.

The applications for the anchors range from the mundane to the exotic. Common applications are mounting parking signs, fence posts, outdoor furniture and speed bumps. Unusual ones anchor jet blast deflectors, runway arresting system (to capture airplanes that overshot the runway) and seasonal flood control systems.

The anchors are popular for seasonal applications where the structure needs to be removed — speed bumps for the winter, tents after a weekend farmer's market. Because they are flush with the surface, then anchor can safely be left installed, for reuse next time

The anchors are offered in different sizes and materials including all stainless steel anchor for use in areas subject to salt water or close to drinking aware reservoirs.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!