Solar Racking: Ballasted or Mechanically Attached?

Mechanically attached racking systems can reduce maintenance costs. Photo courtesy of Fidelity Roof Company.

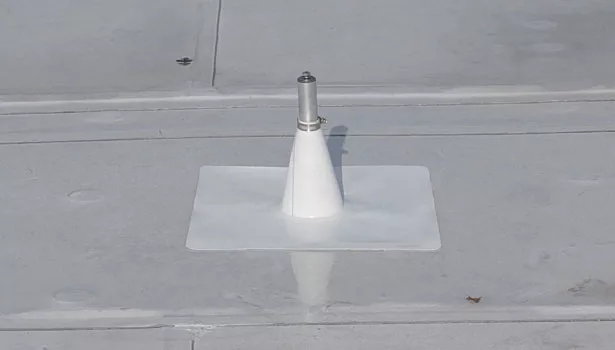

A flashed solar mount. Photo courtesy of Quick Mount PV.

For years the National Roofing Contractors Association (NRCA) and many top solar roofing professionals have discouraged solar contractors from using ballasted racking systems when installing solar arrays on most low-slope roofs. Despite this advice, the vast majority of solar installers continue to use ballasted mounting systems instead of the recommended mechanically attached flashed mounts on low-slope membrane roof systems. So why is this advice from the roofing industry being ignored by so many solar installers?

The first reason ballasted racking systems dominate in solar low-slope installations is that building owners overwhelmingly dislike poking holes in their roofs to mount a solar racking system. Few solar contractors are willing or able to explain that while ballasted systems minimize holes in the roof at first, they will result in higher maintenance costs over the life of the system. The second reason solar contractors prefer ballasted racking is that it eliminates the need to hire a roofer to flash dozens (or hundreds) of solar standoffs. Hiring a roofing subcontractor transfers labor dollars away from the solar installer, and while the final installed cost of the competing methods is not much different, the solar contractor makes less profit when they have to hire a roofer to install the flashed mounts.

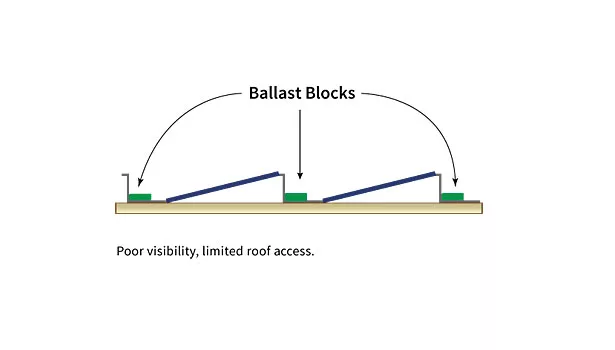

Annual or biannual roof inspection with proactive patching of any suspect areas is key to extending low-slope roof life to more than 20 years. This routine inspection and maintenance is typically mandated for preservation of the roofing warranty. The big knock against ballasted racking systems is they typically cover most of the roof, making inspection and maintenance difficult or impossible without disassembling the major sections of the array.

As a result, minor leaks that would otherwise be easily identified and repaired on a regular roof will often progress to the point of structural water intrusion when hidden under a ballasted array. Once the building owner notices and reports the leak, the solar contractor is then forced to disassemble a large portion of the PV system to allow the roofer to locate and repair the leak. Removing and reinstalling solar modules is an expensive proposition even when the array is young, but as the array ages, PV wire insulation stiffens and cracks more easily, grounding hardware may need to be replaced, racking components can seize and need replacement (also running the risk that the racking components may no longer be available), and PV module damage could result from removal and reinstallation. How many times will systems owners be willing to incur this high cost of leak repair and array removal/reinstallation before they give up on ballasted racking?

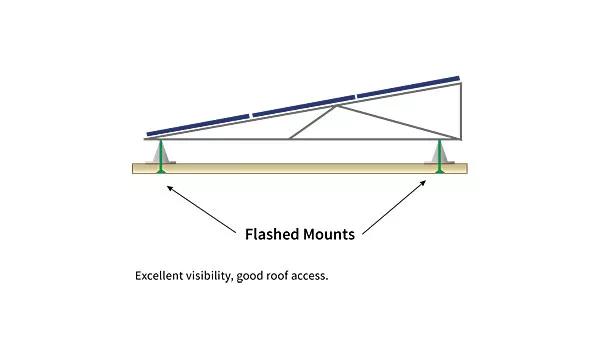

The main benefit of a mechanically attached mounting rack is the installer can design sufficient space under the array to allow for inspection and servicing of the roof under the array. An added benefit is mechanically attached racking systems are lighter on the roof than ballasted systems. This reduced roof load is especially beneficial on roofs without significant load capacity to accommodate heavy ballast blocks.

Another common concern with rooftop solar systems is that often arrays are installed on roofs with less than 15 years of remaining life. Solar PV modules have a productive life of 30 years or more, and there are significant benefits to installing solar on new roofs. The cost to remove and re-install a PV system with ballasted systems to replace a roof can be 20-50 percent of the cost of a brand-new system. Some mechanically attached racking systems allow the roof to be replaced without the need to remove and reinstall the PV system. This is a major cost advantage that provides a better ROI and payback time to the system owner when calculated over the life of the system. Most experienced roofers feel it is acceptable to install solar on a roof that is no more than 3-7 years old, but after that point installing solar on an older roof may not be a wise investment.

The Center’s PV Taskforce

The Center for Environmental Innovation in Roofing’s PV Taskforce is focused on providing high-level thought guidelines for rooftop PV installations. The Center’s PV Racking and Attachment Criteria for Effective Low-Slope Roof System Integration is an easy-to-read discourse about the important criteria rooftop PV designers and installers should consider when installing PV systems on rooftops. External forces, system integration, roof drainage, roof and PV system maintenance, and roof safety are the main principles. Each principle is divided into many specific examples, and each example includes recommended criteria to resolve the issue. This document is applicable to asphaltic-based roof systems, single-ply roof systems and spray polyurethane foam roof systems. For low-slope metal roofs, The Center’s PV Racking and Attachment Criteria for Effective Low-Slope Metal Panel Roof System Integration provides an equivalent discussion. The documents are available at www.roofingcenter.org/.

Additionally, the Center’s PV Taskforce is currently developing PV Racking and Attachment Criteria for Effective Asphalt Shingle Roof System Integration. This will be available in July 2014.

Ballasted racking systems do have their place on some low-slope roofs and may be a more advisable choice for existing built-up roofs that are more than a few years old. Waterproofing reliability on large numbers of built-up flashings on existing built-up roofs may be a challenge, and a ballasted racking system might minimize this leak risk. Even with this exception, the majority of solar-experienced roofers believe that mechanically attached racking is preferable on new BUR roofs and new or existing single-ply roofs.

When ballasted racking systems are used, several design strategies will minimize the problems associated with these systems:

Ponding water is a major concern with any roof. Standing water accelerates roof degradation and it is advisable for solar installers to place the ballast trays in locations that will minimize blocking of drainage pathways. Using ballast-mounting pads (insulation cover board works nicely) reduces or eliminates insulation compression. If insulation does compress under the ballast tray, a small amount of water can accumulate at the perimeter of the ballast tray and attract particulate contamination, forming an abrasive slurry that accelerates the wear of the roof under the ballast tray as the system expands and contracts during the daily thermal cycle. For this reason, it is advisable (and often mandated by roofing warranties) to use a sacrificial slip-sheet on single-ply membrane roofs. Many roofing manufacturers require installers to use their thickest membranes with a slip-sheet also made from the same thickest membrane for a ballasted racking system to be warranted.

Another important consideration is anchorage. While ballasted racking systems don’t require penetration-based mounts to support the load of the array, they may require mechanically attached penetrating anchors, especially in seismically active areas like California. Mechanically attached anchor points prevent excessive movement of the ballasted array during an earthquake or strong windstorms.

Unanchored PV systems can also creep down a roof as a result of vibrational forces from air handling systems or simply as a result of the difference between the expansion/contraction of the metal racking system over a non-metal roofing structure. These forces can be significant, and failure to use sufficient mechanical anchorage could result in separation of the conduit that houses the high-voltage DC cables. If this happens, there is a significant risk of shock or fire. It is inappropriate and dangerous to allow the high-voltage conduit to be the sole point of anchorage for a ballasted system.

Another use for mechanically attached anchors is reducing the need for ballast on roofs that do not have the required load capacity to support heavy ballast blocks.

Solar PV systems that produce the fastest payback and highest ROI are the key to long-term solar success, and mechanically attached racking systems ensure lower maintenance costs over the life of the arrays, delivering the lowest-cost electricity. When building owners and solar contractors fully appreciate the higher lifetime cost of maintenance associated with ballasted racking systems, the solar installation industry will likely shift to mechanically attached racking systems. This will result in additional business opportunities for roofers that have a solar installation division or those roofers that partner with solar installers.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!