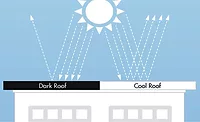

Study Targets Cool Roofs

Assessing the Performance of Cool Roofs in Northern Climates

Much has been written about the use of cool roofs in northern climates. Some authors have raised concerns about the potential for condensation in such roofs, and some have questioned the energy-saving benefits in such climates. However, very little of the published information is generated from actual buildings in operation.

Target Corporation has for approximately two decades installed, almost exclusively, white, mechanically attached thermoplastic PVC roofing membranes on its facilities. These roof systems, which are typically installed over steel decks without a vapor retarder, have performed very well in all climates, and they are still to this day the base design for all of Target’s facilities.

The following summarizes Target’s experience with these roof systems.

Field Experience: Condensation

For decades now, the majority of roofs in America have been constructed without vapor retarders, even in northern climates. This approach to roof design and construction is founded on the principle of the “self-drying roof”: moist air that might migrate to the underside of a membrane and condense in the winter months will migrate to the interior of the building in the summer months. Providing the summertime vapor drive to the interior is greater than the winter time drive toward the cold exterior, the roof will remain dry.

Some have hypothesized that more condensate may form under “cool membranes” than under darker membranes during the winter months, and that they may not heat up sufficiently in the summer months to dry out completely. The net effect, they postulate, would be residual moisture accumulating yearly to the detriment of the roof assembly.

Anecdotal evidence acquired through the re-roofing of stores over many years indicated that the self-drying design principle was effective on Target stores protected by cool roof membranes, even in northern locations. It was decided however to systematically survey stores to confirm that this is in fact the case.

Field technicians investigated the roofs on 26 stores located throughout the states of Connecticut, Illinois, Massachusetts, Michigan, Minnesota, New York, Washington and Wisconsin (ASHRAE climate zones 4, 5 and 6) in August and September of 2013. The roofs ranged in age from 10 to 14 years at the time of the survey — old enough that if condensation was accumulating it would be apparent when the roofs were cut open for examination. All of the roofs surveyed had a white 60-mil PVC membrane mechanically attached to a steel deck, and none had a vapor retarder. The 26 stores can be divided into three categories:

1. Single layer of iso insulation: 11 stores (Table 1)

2. Base layer of iso with an additional layer of iso and/or a cover board: 11 stores (Table 2)

3. Recovers with a ¼-inch gypsum or a ½-inch iso recover board between the new and the old membrane: 4 stores (Table 3)

The technicians randomly chose two locations on each roof for cut tests, with each cut being made over a board joint. Cut tests were all approximately 12 inches by 12 inches in size. The technicians were instructed to cut through all layers down to the steel deck. They were to observe and document the condition (moisture, staining and mold) at the interface between each adjacent layer of the roof system’s components.

After checking all 26 stores, wet insulation was observed in only a single location. In one cut test on a store in Newington, Conn., both layers of insulation were found to be wet. Further investigation revealed the source of moisture to be leakage into the roofing assembly from an adjacent HVAC unit. Two other cut tests were done in other locations on the roof. No moisture was detected at any roof component interface, nor was any staining or mold or other evidence of deterioration observed in either of these two cuts, or in any of the other 50 test cuts taken on the balance of the roofs.

With the advent of a post-consumer PVC recycling program in 2007, Target started removing existing roof membranes as they approach the end of their service life, prior to installing a new PVC sheet. With the exception of areas of localized damage and associated leakage, the insulation, regardless of the store’s location, was found to be sound, dry, fit for re-use and left in place to serve within the new membrane installation. The membrane is collected by their membrane supplier and recycled back into new membrane. The results of this survey are fully consistent with Target’s experience on more than 100 roofs across the continental United States since the PVC membrane recycling and insulation re-use approach was implemented over the past seven years.

Energy Consumption in Northern Climates

The roof represents about three quarters of the building envelope of a typical Target store. It has a disproportionate impact on energy consumption, and is therefore an important element in Target’s ambitious and ongoing efforts to reduce energy consumption.

Specific operational and other costs are confidential information and cannot be disclosed. However it can be stated unequivocally that although the magnitude varies, Target has experienced net energy savings from the use of cool roofs in all but the most extreme climates. Experience gained over approximately two decades has validated the ongoing use of cool roofs across the entire real estate portfolio. Even in climates with lengthy heating seasons, overall cooling costs exceed heating costs in Target’s facilities.

On the few “non-cool” dark roofs Target has in northern climates, the company has not seen any measurable reduction of energy consumption during heating seasons that can be attributed to heat gain via the roof.

Performance and Uniformity of Design

As important as the energy efficiency of their roofing systems is, Target cannot sacrifice performance to achieve it. Keeping their facilities dry in all climates is critical, as is durability. Target meets all of the company’s performance objectives by standardizing its base roofing design on a roofing system with decades of proven performance. Furthermore, the institutional knowledge developed by people within the Target organization by using the same roofing system in all locations enables them to manage all aspects of their roofs in the most cost-effective manner throughout the entire life cycle of their buildings.

With more than 2,000 stores, distribution centers, offices and other buildings, and by the very nature of the geometry of most of their buildings, roofs are a critical element to Target Corporation. Over the past two decades, the use of thermoplastic cool PVC roofing systems have been an important component in achieving performance, energy efficiency, sustainability and operational goals in their facilities.

Check out the full version of the article at Architectural Roofing & Waterproofing.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!