It’s estimated, there are over 1 million outdated 4X8 industrial skylights in use throughout the greater Los Angeles area. These skylights limit daylighting performance, are prone to leaking and pose serious fall safety risks for rooftop workers.

For over 40 years, Data Aire has manufactured air control systems for data processing centers. The high-tech manufacturing facility in Orange, Calif. upgraded their warehouse daylighting system, saving on energy costs, ensuring worker safety and improving work conditions.

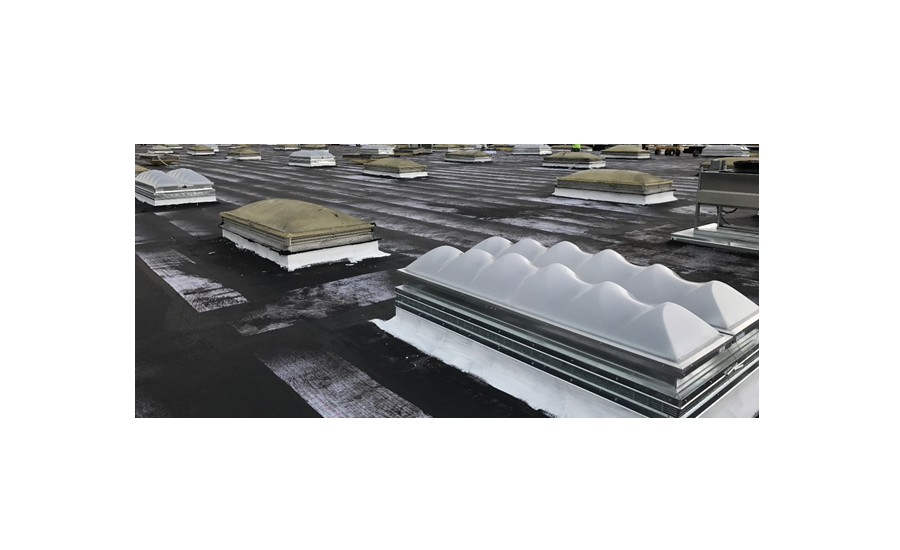

A mix of 30 UL Listed Smoke Vents and 58 SKYPRO Industrial Skylights replaced the existing fiberglass units. Each new unit comes with a high performance polycarbonate dome, aluminum capped frame, 50 year silicone seal and continuous gaskets. An extreme weather rated VORTEX venting base was added to each unit for proper interior ventilation.

The new polycarbonate industrial skylights and smoke vents were part of a re-roof project that brought the building up to Title 24 standards. The entire project was managed by Westcoast Roof Consulting and performed by commercial roofer, Howard Roofing.

A light study was performed pre and post project, both times at 12:00pm on partly cloudy days. It is always recommended when comparing light conditions to test at the same time of day and similar weather.

The light study revealed the original Foot Candles (FC) in Data Aire’s warehouse were an average of 9 FC. With the new Skyco Skylights units, the FC increased an average of 120 FC (the industrial skylights registered an average of 150 FC while the smoke vents hit 90 FC).

The minimum recommended illumination for a warehouse that performs detailed mechanical work is 75 to 100 FC. Providing proper interior natural light for workers contributes to increased production quality and team morale.

“The old skylights drastically limited the daylighting inside the warehouse. We see this case with a lot of buildings in the Southwest due to the extreme sunlight’s deteriorating effect on fiberglass and acrylics,” explains Paul Simony, Skyco Skylights VP of sales and lighting guru.

This picture shows a visual comparison of the original fiberglass skylights and the new polycarbonate skylights and smoke vents by Skyco Skylights. Smoke vents were the first units to be replaced followed by the industrial skylights with VORTEX venting base.

The polycarbonate industrial skylights and smoke vents have a 70 percent Visible Light Transmittance and 0.58 Solar Heat Gain Coefficient (single dome SKYPRO white). These skylights are ICC-ES

Listed (ESR- 3837) and third party tested to withstand 800 lbs. impact load. The improvements in lighting and savings on energy costs are tremendous. For added security and Cal/OSHA Fall Protection compliance, white powder coated Security Bars (aka Burglar Bars) were installed on the curb of each skylight and smoke vent opening.

In many cases, facility managers can save upwards of 15 percent on their electrical costs by switching to new polycarbonate skylights. The low Solar Heat Gain Coefficient of the polycarbonate combined with the new “cool roof” by Howard Roofing will significantly decrease cooling costs in the hotter months.

Replacing old underperforming skylights with new polycarbonate units can be a big project. One that many building owners tend to put off until the absolute latest possible time. Aside from the energy cost savings, new polycarbonate skylights drastically decrease building owner’s long term liabilities (when combined with Cal/OSHA compliant security bars). For skylights 5 years in age or more, it is highly recommended to have a thorough evaluation of their performance and safety.

Report Abusive Comment